Chemical reactions of aluminium sheets with other substances

Aluminium sheet can be used as a base to form salts with acids, or as a weak acid to form salts with strong bases. It is stable in air because exposure to air results in the formation of a thin, transparent oxide film that protects the aluminium sheet from further oxidation and reactions. The growth of this natural oxide film is self-limiting, i.e. when a thin layer is formed, further growth ceases. Molten aluminium is protected in air by a thicker oxide layer, which also prevents further oxidation. Finely atomised or flaked aluminium can explode violently when mixed with air and ignited. Aluminium sheets react rapidly with boiling water, giving off hydrogen and forming aluminium hydroxide.

In its ultra-pure state (99.99%), aluminium sheet lacks strength and hardness, but is formable, weldable, corrosion resistant and an excellent conductive material. Ultra-pure aluminium has many uses: in chemical equipment, reflectors, petrol catalysts, jewellery, electronic components. However, most aluminium sheets in use today are alloyed with other elements to add strength.

The common alloying elements are manganese (Mn), magnesium (Mg), copper (Cu), zinc (Zn) and silicon (Si). Small amounts of bismuth (boron), zirconium (titanium) and especially lithium (titanium) and zirconium (titanium) alloys are added in aerospace. Iron is an impurity.

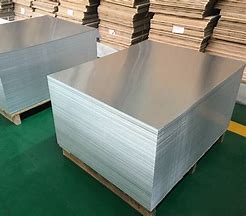

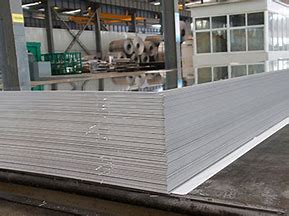

Aluminium sheet products can be formed in foundries by sand casting, or die casting, or cast into cylindrical or rectangular blocks and machined or forged into products such as plates, sheets, forgings or extrusions.

* Thank you for your inquiry. Please provide your business needs information so that we can better serve you.

This information can help us assign the most suitable person to solve your problem. We will give you feedback within 1-2 working days.

Related Blog