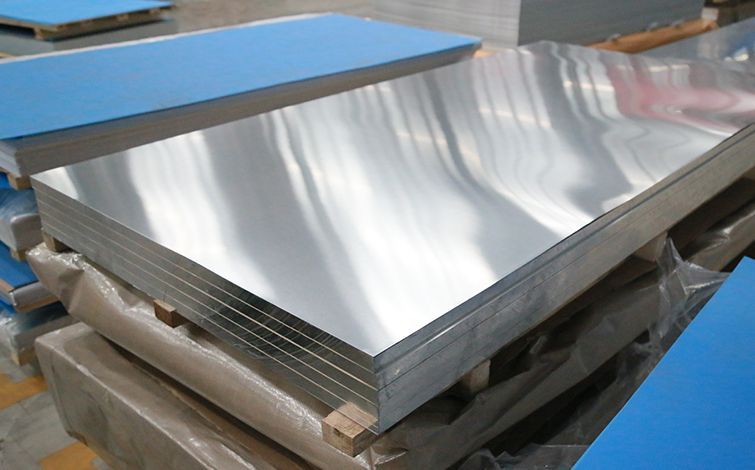

Characteristics and applications of Series 2 aluminium-copper alloys

Series 2 aluminium alloys, also known as hard aluminium, have copper as the main alloying element. The representative grades are 2017 and 2024 aluminium sheet: it has high strength and good cutting performance, certain heat resistance and can be heat treated, the disadvantage is that the corrosion resistance is poor. The main common states are O, T3, T351, T361, T4, T81, etc.

2 series aluminium-copper alloy features.

1、High hardness, aluminium-copper alloy is invented by people to solve the problem of soft texture of aluminium. It can be said that the biggest characteristic of 2 series aluminium-copper alloy is high hardness, so 2 series aluminium sheet is very suitable for processing parts, and its performance can be comparable with steel.

2, 2 series aluminium alloy still has high strength under high temperature, aluminium - copper - magnesium - iron - nickel alloy in 150-250 degrees Celsius process performance is excellent, can be used to process heat-resistant parts under high heat conditions; aluminium - copper - manganese alloy in 225-250 degrees Celsius the highest strength.

3、It can be strengthened by heat treatment. 2 series aluminium sheets can be strengthened by heat treatment in the whole series, and its hardness will be further increased after annealing and quenching.

4, 2 series aluminium alloy has good welding performance, especially aluminium-copper-manganese alloy, can maintain good performance at high temperature, easy to weld, commonly used in heat-resistant, weldable forgings and structural parts.

2 series aluminium-copper alloy uses.

Series 2 aluminium belongs to aviation aluminium, aluminium sheets are mainly used in aircraft structures (such as skins, etc.), spacecraft, engines, pistons, automobile hulls, ship hulls and stressed components, etc.

* Thank you for your inquiry. Please provide your business needs information so that we can better serve you.

This information can help us assign the most suitable person to solve your problem. We will give you feedback within 1-2 working days.

Related Blog