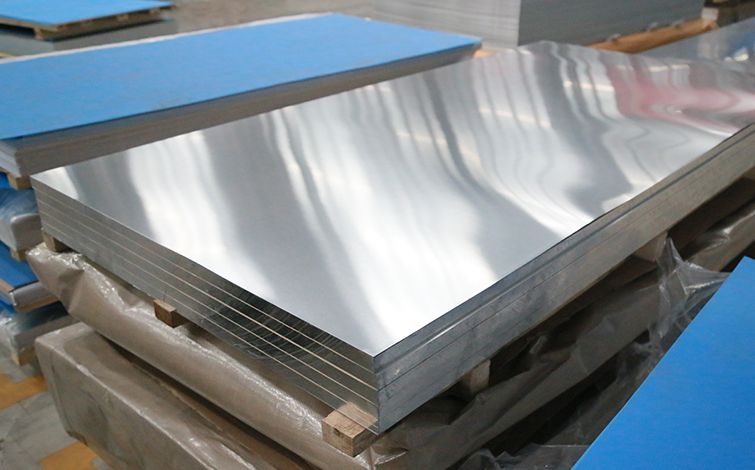

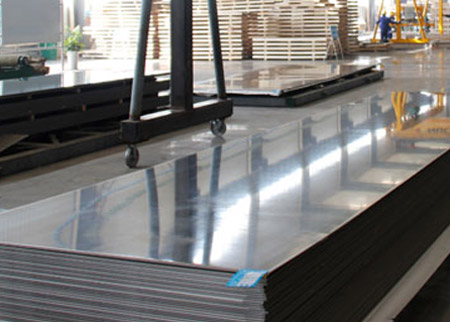

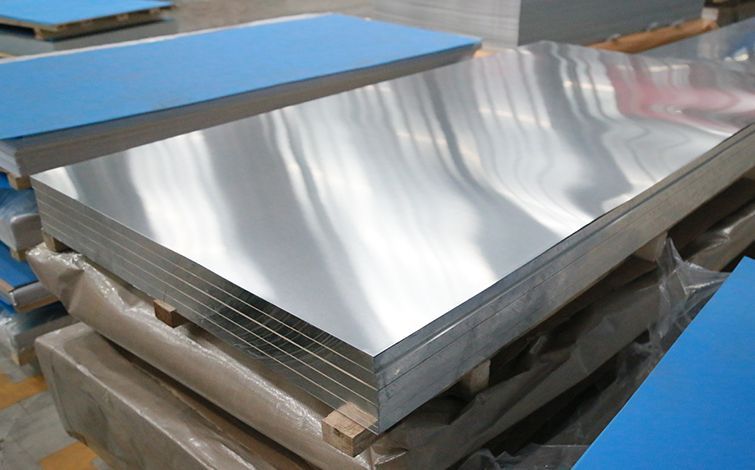

Aerospace aluminium alloys are the backbone of aircraft and spacecraft manufacturing. Along with the increasing requirements for flight performance, payload, fuel consumption, service life and safety and reliability in the design and manufacture of contemporary aircraft, the comprehensive performance and reduction effect of aerospace aluminium alloy structures have also put forward higher and higher requirements. The use of CNC milling of large aluminium alloy materials to produce monolithic aluminium alloy structural components, instead of the traditional combination of several high-end aerospace aluminium alloy components assembled together, can not only achieve significant weight reduction of structural components, improve the reliability of the service process, but also reduce the aircraft assembly process and reduce manufacturing costs. This advanced design and manufacturing method places very demanding requirements on aluminium alloy materials: the maximum thickness of aluminium alloy forgings or pre-stretched plates often needs to be 150mm or more, with a high degree of uniformity in the overall performance of the different thickness components, while also possessing excellent strength - plasticity - fracture toughness - fatigue resistance - and matching stress corrosion and spalling corrosion resistance.

Aluminium is used as the main propellant in the solid rocket booster engines of the Space Shuttle because of the high bulk energy density of high-end aerospace aluminium alloys and the difficulty of accidental ignition.

Aluminium alloy sheets are used in a large number of aerospace applications with complexity and performance requirements ranging from simple components to major load-bearing structures in aircraft such as the Airbus A340 and Boeing 777.

The aircraft and aerospace industries have long relied on aluminium alloys. Without the use of aluminium alloys in engines, the first aircraft would never have been able to fly. Artificial satellites are made from high-end aerospace aluminium alloys, so that they can survive the journey through our hot outer atmosphere and into space. Even today, NASA still uses aluminium-lithium hybrids in its advanced Orion spacecraft.

* Thank you for your inquiry. Please provide your business needs information so that we can better serve you.

This information can help us assign the most suitable person to solve your problem. We will give you feedback within 1-2 working days.

Related Blog