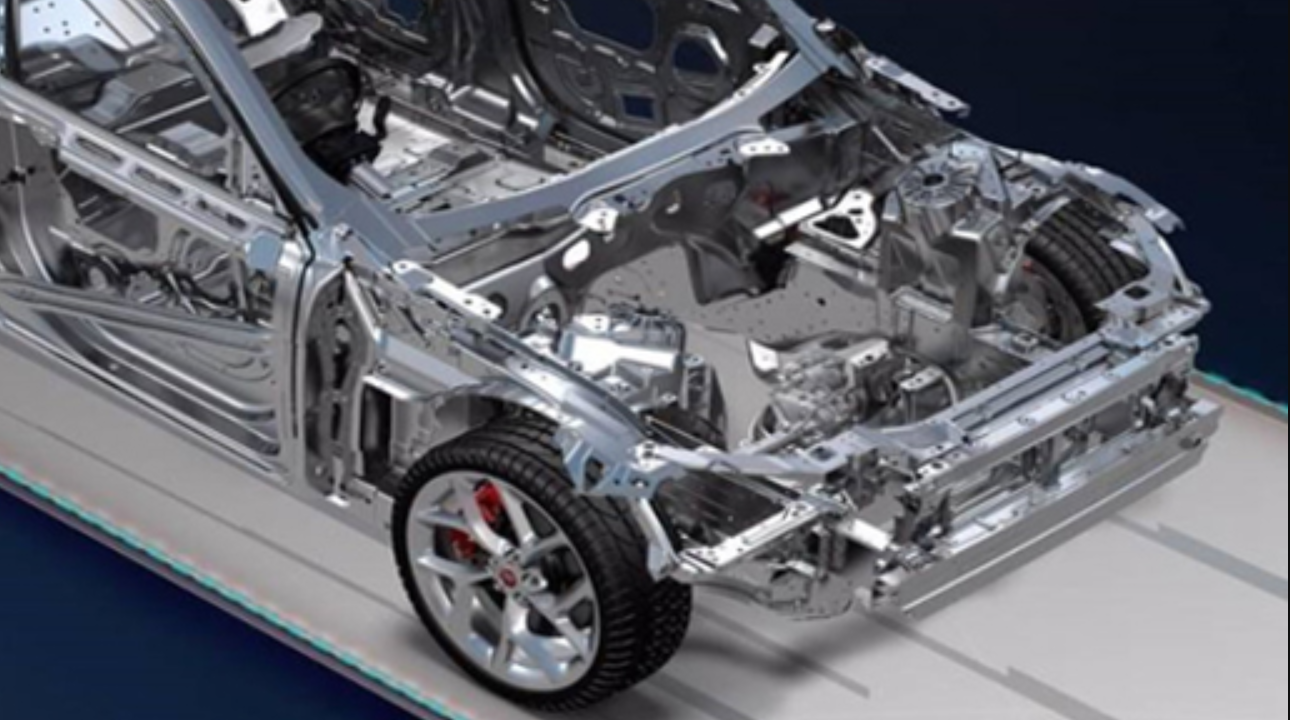

New energy vehicle power battery, because of its own weight defects and energy density demand contradiction, in the whole vehicle parts subsystem, lightweight demand is particularly urgent.

In the power battery, the tray accounts for 20-30% of the weight of the battery system, and is in fact the main structural component. Therefore, under the premise of ensuring the functional safety of the battery, the light weight of the tray becomes one of the main targets for improvement of the structural parts of the battery.

From the evaluation of the comprehensive material index, aluminium alloy, first of all, can meet the structural needs of vehicle components including the battery system, and is still the material to replace part of the steel structure. However, high-strength steel plates are themselves following the path of lightweight technology. As a result, aluminium alloy and lightweight high-strength steel plates have been in a stalemate on the road to material selection.

Aluminium and steel in a stalemate

Aluminium is generally the main solution for companies to achieve light weight, as it follows the development trend of energy saving, environmental protection and light weighting of products. However, lightness is not the only consideration for vehicle manufacturers when choosing materials, nor is cost.

There is no doubt that aluminium has a clear effect on lightweighting and will therefore be used more and more in the future. Despite the high cost of aluminium, its excellent processability, low density (2.7g/cm for aluminium alloys), corrosion resistance and high recyclability are clear advantages and are still important markers in the lightweighting process of electrified new energy vehicles.

Ducker Global Consulting has conducted research and forecasts on average vehicle aluminium use in North America and found that aluminium use in vehicles has shown a year-on-year increase since 1996 and has been on the rise since 2012, reaching 400lb/vehicle (181kg/vehicle) in 2015, exceeding 450lb/vehicle (204kg/vehicle) by 2020 and exceeding 550lb/vehicle by 2028. By 2028, it will exceed 550 lb/vehicle (249 kg/vehicle).

* Thank you for your inquiry. Please provide your business needs information so that we can better serve you.

This information can help us assign the most suitable person to solve your problem. We will give you feedback within 1-2 working days.

Related Blog