Electronic aluminum foils are an essential component of the electronic industry. They are used as conductors, capacitors, transformers, and various other electronic components. Aluminium foils are preferred in the electronic industry due to their excellent electrical conductivity, lightweight, and durability. To make electronic aluminum foils, manufacturers use different aluminum alloys. In this article, we will discuss the different aluminum alloys used for electronic aluminum foils.

1050 aluminum alloy is a popular choice for electronic aluminum foils because of its excellent electrical conductivity. It contains 99.5% aluminum, which makes it highly conductive. This alloy is also easy to form and has good corrosion resistance. 1050 aluminum alloy is used in capacitors, transformers, and other electronic components. Moreover, it is also used in packaging and insulation materials.

1100 aluminum alloy is another popular choice for electronic aluminum foils. It contains 99% aluminum, which makes it highly conductive. This alloy is also easy to form and has good corrosion resistance. 1100 aluminum alloy is used in electrical conductors, heat exchangers, and other electronic components. Moreover, it is also used in the construction industry for roofing and cladding.

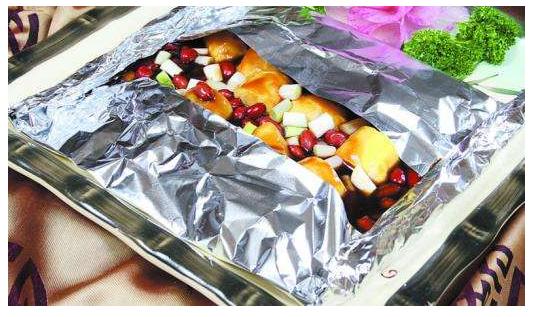

3003 aluminum alloy is a widely used alloy for electronic aluminum foils. It contains 1.2% manganese and 0.12% copper, which improves its strength and conductivity. This alloy is also easy to form and has good corrosion resistance. 3003 aluminum alloy is used in heat sinks, electronic housings, and other electronic components. Moreover, it is also used in the food and beverage industry for packaging.

Aluminum alloys are widely used in the electronic industry because of their excellent electrical conductivity, lightweight, and durability. 1050, 1100, and 3003 aluminum alloys are commonly used in electronic aluminum foils. These alloys are used in the manufacturing of electronic components, packaging materials, heat sinks, and many other applications in different industries. The selection of a specific aluminum alloy depends on the specific application and the desired properties required.

* Thank you for your inquiry. Please provide your business needs information so that we can better serve you.

This information can help us assign the most suitable person to solve your problem. We will give you feedback within 1-2 working days.

Related Blog