Aviation aluminum alloys have a characteristic that it is difficult to weld. During the welding process, aviation aluminum alloy has the following problems:

(1) Very easy to oxidize. In air, aluminum is easily oxidized to form a dense aluminum oxide film. The surface of the alumina film is easy to adsorb moisture, and when welding, it hinders the fusion of base metals, and it is easy to form pores, slag inclusion, unfused and other defects, causing the performance of the weld to decrease.

(2) Easy to produce pores. The main reason for the porosity of aluminum and aluminum alloy welding is hydrogen, because liquid aluminum can dissolve a large amount of hydrogen, while solid aluminum almost does not dissolve hydrogen, so when the molten pool temperature is rapidly cooled and solidified, hydrogen does not have time to escape, and it is easy to accumulate in the weld to form pores.

(3) The weld has a large tendency to deform and form cracks. The linear expansion coefficient and crystallization shrinkage of aluminum are about twice that of steel, which is prone to large internal stress of welding deformation, and will promote the generation of hot cracks for structures with greater rigidity.

(4) The thermal conductivity of aluminum is large. It is about 4 times that of steel, so when welding aluminum and aluminum alloys, it consumes more heat than welding steel.

(5) Evaporative burning of alloying elements. Aluminum alloy contains elements with low boiling point (such as magnesium, zinc, manganese, etc.), which are easily evaporated and burned under the action of high temperature arc, thereby changing the chemical composition of the weld metal and reducing the performance of the weld.

(6) Low high temperature strength and plasticity. At high temperatures, the strength and plasticity of aluminum are very low, which destroys the forming of the weld metal, and sometimes it is easy to cause the weld metal to collapse and weld penetration.

(7) No color change. When aluminum and aluminum alloys are converted from solid to liquid, there is no obvious color change, making it difficult for operators to grasp the heating temperature.

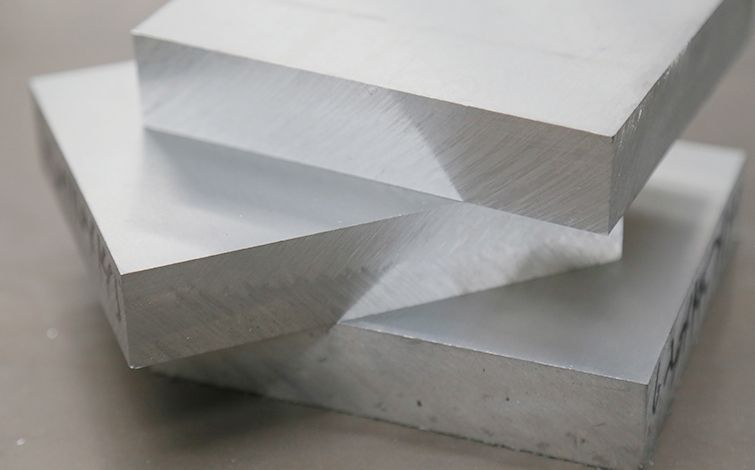

In view of the welding difficulties of aluminum alloys, aviation aluminum alloys are manufactured through thermal deformation and manufacture of integral structural parts, which is a development trend.

* Thank you for your inquiry. Please provide your business needs information so that we can better serve you.

This information can help us assign the most suitable person to solve your problem. We will give you feedback within 1-2 working days.

Related Blog