Aluminium alloy ingredient selection for the melting of high quality aluminium melts

The production of aluminium alloys requires many processes, including melting and pouring, and the melting and pouring of alloys is a major part of casting production. Strict control of the entire melting and casting process plays an important role in preventing casting defects such as pinholes, inclusions, under-casting, cracks, porosity and shrinkage. Due to the high tendency of aluminium melt to absorb hydrogen, strong oxidation ability and easy dissolution of iron, easy and careful preventive measures must be taken during the melting and casting process in order to obtain high quality castings. We will then introduce how we at Haomei Aluminium deal with the melting and casting of aluminium alloys to be able to produce the optimum aluminium alloy products.

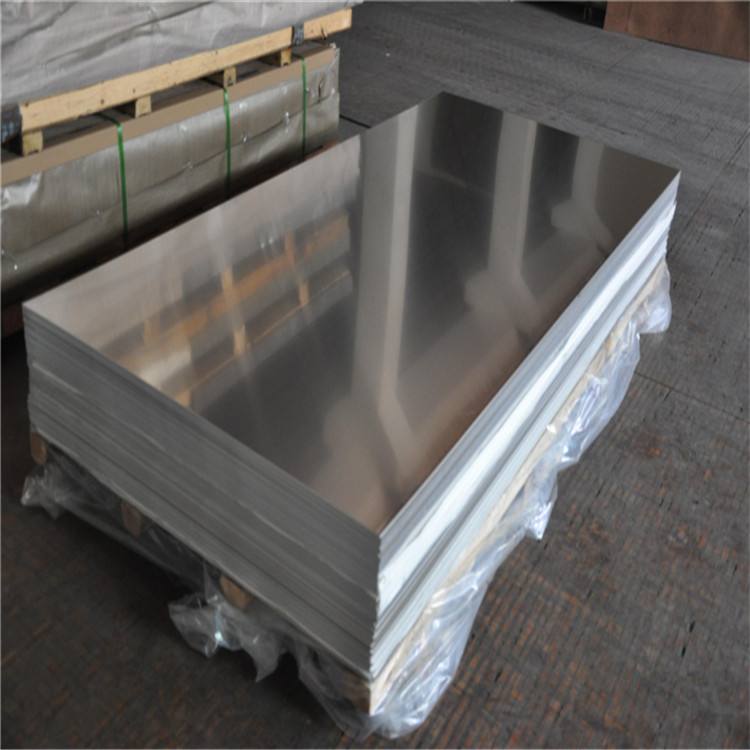

First of all we need to understand the selection and quality control of the aluminium alloy furnace charge, as this is the basis for melting good quality aluminium. In order to produce a high quality aluminium melt, the first step is to select a qualified raw material. Scientific management and appropriate treatment of raw materials are required, otherwise the quality of the alloy will be seriously affected. Production practice proves that poor control of raw materials (including metal materials and auxiliary materials) will cause the castings to be scrapped in batches. Therefore, the raw materials of aluminium alloy must have qualified chemical composition and organization, and their specific requirements we will explain in detail in the future, so we Haomei Aluminium Co., Ltd. suggest you pay more attention to our company's official website, or if you have any questions, you can contact us directly to send an email. The alloy ingot into the factory in addition to the analysis of the main components and impurity content, still on the check low with the organization and fracture. Practice has proved that the use of aluminum containing serious shrinkage, pinholes, and bubbles, it is difficult to obtain dense castings, and even cause the whole furnace, the whole batch of castings scrap.

* Thank you for your inquiry. Please provide your business needs information so that we can better serve you.

This information can help us assign the most suitable person to solve your problem. We will give you feedback within 1-2 working days.

Related Blog