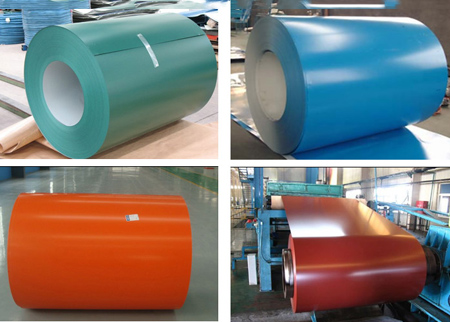

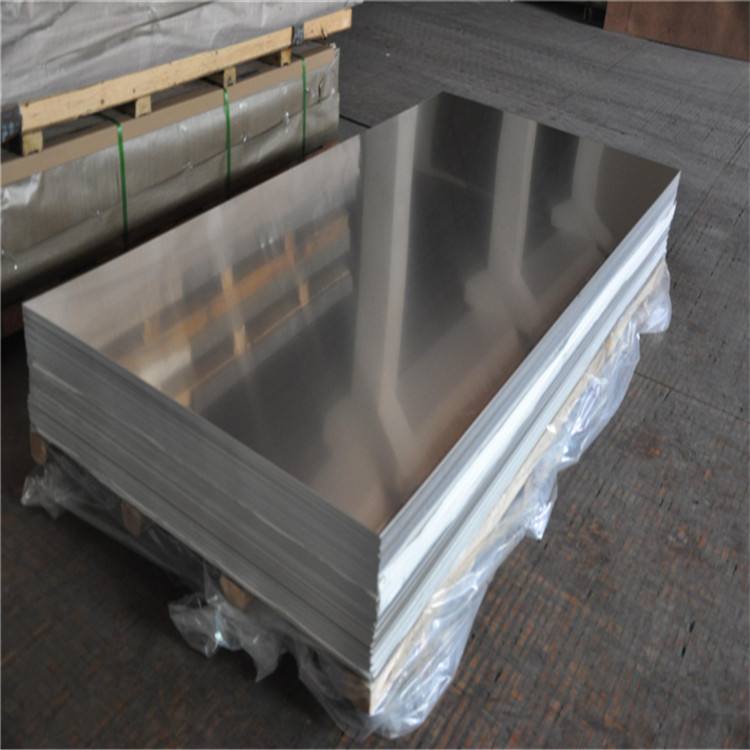

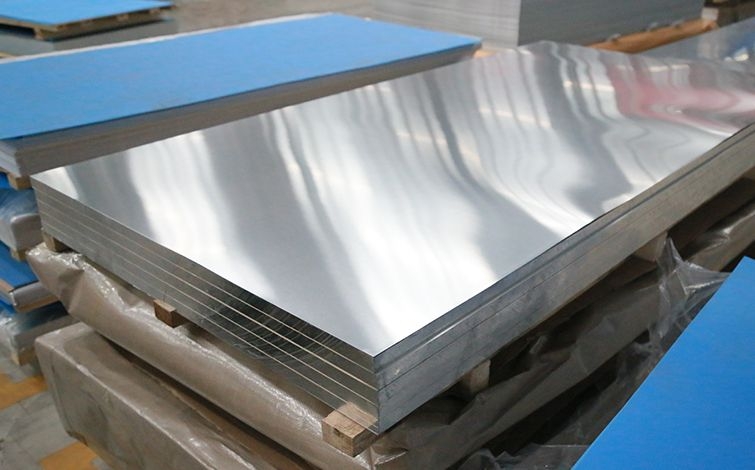

Al-Mg-Mn panels are an efficient and economical material for building facades and roofs. Aluminium alloys have been widely used in the construction industry, and aluminium-magnesium-manganese sheets as aluminium for construction are no exception, and they play an important role in the development of modern architecture in terms of comfort, magnesium-manganese aluminium sheet supports, lightness, economy and environmental protection. Among them 3003 and 3004 have been widely used 50 years ago due to their structural strength, weather resistance, pollution resistance and good resistance to bending and welding. In addition, we can also use aluminium 5052 and 6061 aircraft grade alloy materials, which are highly resistant to corrosion.

Its uses when used as aluminium for construction include the installation of vapour barriers like in condensation-proof designs. The aluminium is located on the side where the vapour enters the room, so the heated room should be placed inside the insulation and the cold room should be located on the outer layer of the insulation. The choice of laminated veneer material is ideal, while aluminium foil veneer is prone to rusting under the action of water vapour and should be avoided where possible. Ventilation interlayer or exhaust trench: outside the insulation layer and between the roof board, such as ventilation interlayer, due to the continuous indoor penetration of steam, can be brought out through the airflow of constant exchange with outdoor air, so that the insulation layer air dry.

The magnesium aluminium manganese panels have three main advantages:

One, is that the total cost is lower than that of colour steel tiles. Magnesium aluminium manganese alloy plate low density, the same weight, the purchase of higher than the colour steel 1/3. in the same quality, thickness of the same case, the colour aluminium square than the colour steel 3 times larger. For example, you buy a ton of aluminum-magnesium-manganese alloy plate, it is 3 times larger than the color steel.

Second, is the aluminum magnesium manganese alloy plate itself has corrosion resistance. General colour steel tile with 3-5 years, will be corroded, serious also need to replace, renovation, the cost of natural increase. After choosing aluminum magnesium manganese alloy plate instead, its service life can reach 50 years, not subject to man-made damage. Especially acid rain heavy, corrosion speed of the area, with color aluminum instead of color steel do, custom aluminum magnesium manganese plate, has become a major trend.

Third, is high recycling value. After the coloring steel rust, a kilogram can only be recycled a few cents. And color aluminum plate late after hand is the original price 8.5-9.5 discount, recycling value is obviously higher than color steel tile.

* Thank you for your inquiry. Please provide your business needs information so that we can better serve you.

This information can help us assign the most suitable person to solve your problem. We will give you feedback within 1-2 working days.

Related Blog