As a professional manufacturer of aluminum-magnesium-manganese plates, our products of Haomei Aluminum Co., Ltd. are developing by leaps and bounds like the aerospace industry. Today we lead you to understand the application of aerospace aluminum alloy for sale.

First of all, let's understand the two major types of structural materials used in spacecraft: metal materials and composite materials. Metal materials have mature performance and processing and manufacturing foundation, and have always been the first choice for satellite structural materials; As an emerging material, composite materials are favored by researchers for their outstanding advantages such as low density and strong designability, and there is a trend of gradually replacing metal as the main structural material of satellites.

As the main manufacturing material of spacecraft, aluminum alloy requires a large number of aluminum alloy materials from fuel tanks, manned capsules (escape capsules), orbital modules, etc. So, what are the main aluminum alloys for aerospace?

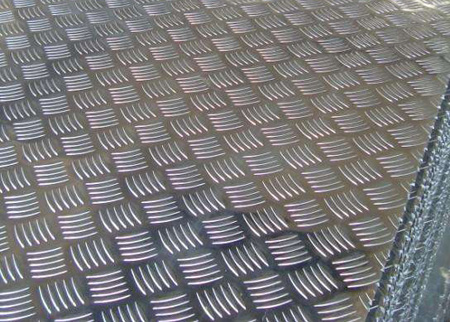

Aluminum alloy large extruded profiles, aluminum lithium alloy, aluminum alloy thick plate, aluminum alloy castings have become the first choice for aerospace aluminum alloy. In the process of aluminum alloy material research and development and production, it is necessary to overcome a number of process problems and obtain a number of scientific research achievements such as melting, hot working, heat treatment, etc. The specific series includes aluminum-magnesium-manganese plates.

Among the lightweight alloys, aluminum alloy is relatively cheap, has good thermal conductivity, good electrical conductivity and good corrosion resistance, and is currently the most widely used light metal material on satellites. Some aluminum alloys also have good low-temperature properties, and their strength and plasticity increase as the temperature decreases. In the classic space shuttle era, the crew compartment, front fuselage, middle fuselage, rear fuselage, vertical tail, flaps, lifting ailerons and horizontal tail were all made of aluminum alloy. In the United States, the main research and application is 7 series aluminum alloys such as 7075, 7475 and 7055. These components of aluminum alloy not only have high strength, but also high toughness, has always been the goal of aerospace materials researchers in various countries. Limited by the development of material preparation technology, the relative application of high-strength aluminum alloys is few, but to achieve lightweight design of spacecraft, this is always a direction worth studying.

* Thank you for your inquiry. Please provide your business needs information so that we can better serve you.

This information can help us assign the most suitable person to solve your problem. We will give you feedback within 1-2 working days.

Related Blog