Aluminum cans are made primarily of aluminum, which is a lightweight, durable, and versatile metal that is abundant in the earth's crust. Sheets of aluminum are the third most common element, after oxygen and silicon, and its unique properties make it an ideal material for a variety of applications, including packaging.

To make aluminum cans, manufacturers start by mining bauxite, a reddish-brown rock that contains aluminum oxide. Bauxite is typically found in tropical and subtropical regions, such as Africa, the Caribbean, and South America. Once mined, the bauxite is refined into alumina, a white powder that is further processed into aluminum metal using the Hall-Héroult process.

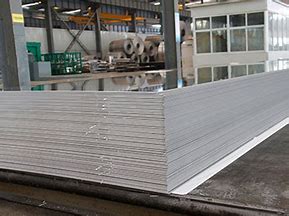

The Hall-Héroult process involves passing an electric current through a molten mixture of alumina and cryolite, a mineral that acts as a solvent for the alumina. The electric current breaks down the alumina into aluminum and oxygen, which separate and settle at the bottom of the tank. The aluminum is then siphoned off and poured into ingots, which are sent to rolling mills to be turned into thin sheets.

The thin sheets of aluminum are then sent to can manufacturers, who use special machines to shape the sheets into cans. These machines also apply a thin layer of polymer or lacquer to the inside of the can to prevent the aluminum from reacting with the contents and altering the taste. The cans are then filled with the beverage of choice and sealed with a lid.

Aluminum cans are a popular choice for packaging beverages, such as soda, beer, and energy drinks, because they are lightweight, easy to transport, and can be recycled indefinitely without losing quality. In fact, recycling aluminum cans saves energy and reduces greenhouse gas emissions, making it an environmentally friendly choice for consumers and manufacturers alike.

Overall, aluminum cans are a simple and effective solution for packaging drinks, and their widespread use has helped to reduce waste and promote sustainability. With ongoing innovation in the materials and processes of sheets of aluminum used to make aluminum cans, they are likely to remain a popular choice for consumers and manufacturers for years to come.

* Thank you for your inquiry. Please provide your business needs information so that we can better serve you.

This information can help us assign the most suitable person to solve your problem. We will give you feedback within 1-2 working days.

Related Blog