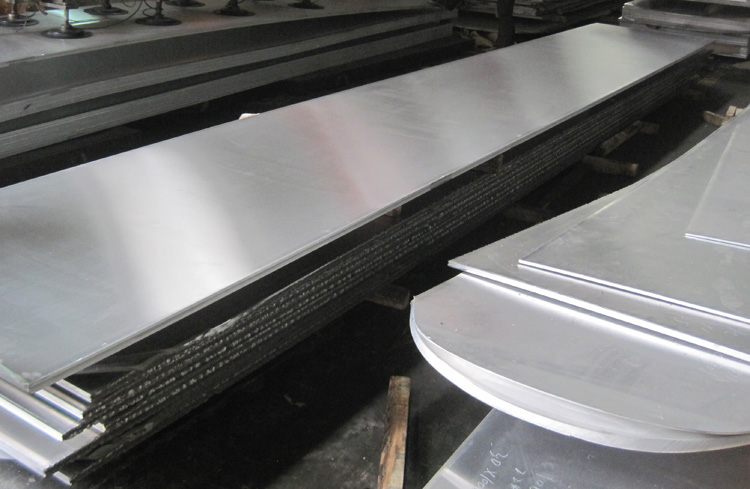

Aluminum alloys have established themselves as one of the most versatile materials in various industries. They are used in a wide range of applications, from aircraft and automobiles to construction and packaging. One of the main reasons why aluminum alloys are so popular is because they are stronger than pure aluminum. But, what makes them stronger?

To understand why aluminum alloys have better mechanical properties than pure aluminum, we need to dive into the science behind them. Aluminum alloys are a combination of aluminum and other elements such as copper, zinc, magnesium, or silicon. These elements are added to aluminum in specific proportions to create a solid solution that has enhanced properties.

The addition of other elements to aluminum changes its crystal structure, which creates a stronger and more resistant material. For example, adding copper to aluminum improves the strength of the alloy by forming a precipitate that reinforces the alloy's structure. Similarly, adding magnesium to aluminum makes the resulting alloy more corrosion-resistant and stronger.

Moreover, the alloying process allows manufacturers to tailor the properties of the alloy to meet specific needs. By combining different elements in different proportions, manufacturers can create alloys with exceptional properties like high strength, light weight, and corrosion resistance. For example, the 6061 aluminum alloy, which contains magnesium and silicon, is highly corrosion-resistant, has excellent weldability, and is commonly used in aerospace and structural applications.

In addition to the benefits of the alloying process, aluminum alloys have other advantages. They are lightweight, which makes them ideal for transportation applications. They are also highly corrosion-resistant, which makes them suitable for outdoor and marine applications. Aluminum alloys are also ductile, which means they can be easily formed into different shapes and sizes.

In summary, the addition of other elements to aluminum creates a stronger and more versatile material that can meet various requirements and applications. Whether in construction, transportation, or manufacturing, aluminum alloys have proven to be a reliable and effective material in a wide range of industries.

Aluminum alloys also have a higher strength-to-weight ratio than pure aluminum, which makes them ideal for applications where weight reduction is critical. This property is particularly important in the aerospace industry, where reducing the weight of aircraft components can lead to improved fuel efficiency and cost savings. Therefore, aluminum alloys have become the material of choice for many aircraft components, including wings, fuselages, and landing gear.

* Thank you for your inquiry. Please provide your business needs information so that we can better serve you.

This information can help us assign the most suitable person to solve your problem. We will give you feedback within 1-2 working days.

Related Blog