What types of aluminium foil are there?

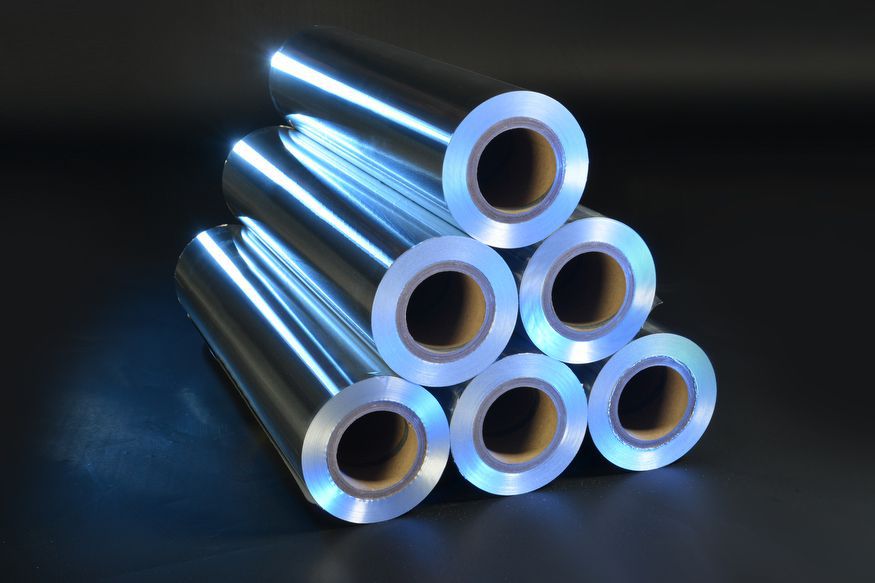

Aluminium foil is a thin strip of aluminium and aluminium alloy with a thickness of ≤ 0.2mm. Its stamping effect is similar to that of pure silver foil stamping and is therefore also known as false silver foil. Due to its soft, ductile texture and silvery-white lustre, aluminium foil can also be printed if the sheet is calendered and laminated onto offset paper with substances such as sodium silicate. Aluminium foil is generally classified according to its thickness, state and use.

By thickness: any aluminium foil greater than 0.012mm is called a single foil, less than or equal to 0.012mm is called a double foil; also the thickness with a zero after the decimal point is called a single zero foil, and the thickness with two zeros after the decimal point is called a double foil.

By state: it can be divided into full hard foil, soft state foil, semi-hard foil, 3/4 hard foil and 1/4 hard foil. Fully hard foil is foil that has not been annealed after rolling (fully annealed strip coil and >75% cold rolled); soft state foil is foil that has been fully annealed after cold rolling; where the tensile strength of aluminium foil is between fully hard foil and soft state foil it is called semi-hard foil; where its tensile strength is between fully hard foil and semi-hard foil it is 3/4 hard foil; where the tensile strength of aluminium foil is between soft state foil and semi-hard foil it is called 1/4 hard foil.

According to the surface state: it can be divided into single-sided glossy foil and double-sided glossy foil. Aluminium foil rolling is divided into single-rolling and double-rolling. When single-rolling, both sides of the foil are in contact with the roll surface and both sides have a bright metallic lustre, known as double-sided glossy foil. In double rolling, only one side of each foil is in contact with the rolls, the side in contact with the rolls is bright and the two sides of the foil in contact with each other are dark, this foil is called single-sided foil. The minimum thickness of a double-sided foil depends mainly on the size of the working roll diameter and is usually no less than 0.01mm. The thickness of a single-sided foil is usually no greater than 0.03mm, with the current minimum thickness being 0.004mm.

According to the use of aluminium foil: it can be mainly divided into aluminium foil for packaging, aluminium foil for air conditioning, aluminium foil for electronics and aluminium foil for batteries, etc.

* Thank you for your inquiry. Please provide your business needs information so that we can better serve you.

This information can help us assign the most suitable person to solve your problem. We will give you feedback within 1-2 working days.

Related Blog