What is the surface treatment of aluminium sheets? Why do aluminium sheets need a surface treatment?

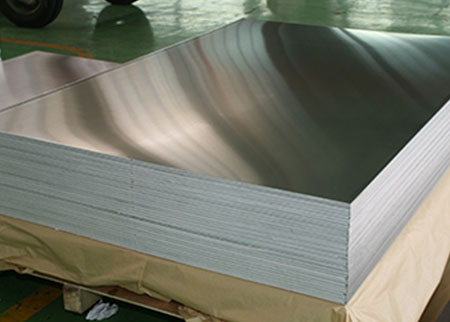

When aluminium sheets are first extruded, they are called substrates and generally have a plain bright silver appearance. This unsurfaced substrate is not yet suitable for direct use in windows and doors, firstly because the appearance is mediocre and not good enough, and secondly because aluminium without a protective layer is not well adapted to the environment, weather resistant and susceptible to erosion. The most common surface treatments for home windows and doors on the market can be broadly divided into five types of anodic oxidation, electrophoresis, powder coating, fluorocarbon spraying and wood grain transfer printing. So what is the difference between these different surface treatment processes? How do you choose? Let's take a look at anodic oxidation today.

Anodising.

Process: put the cleanly treated aluminium plate into a water filled with and some solvents and dip it, then bake it, then you will have a glossy and very beautiful aluminium plate out of the oven - the process of using aluminium or aluminium alloy products as the anode placed in an electrolyte solution and using electrolysis to form a thin film of aluminium oxide on its surface.

Features: smooth surface, strong metallic texture and relatively little colour.

Market situation: because of the equipment and process, only large aluminium sheet factories can do it, the quality is very guaranteed, mostly seen in the surface treatment of large quantities of profiles, the proportion of appearances on home decoration doors and windows is not high

* Thank you for your inquiry. Please provide your business needs information so that we can better serve you.

This information can help us assign the most suitable person to solve your problem. We will give you feedback within 1-2 working days.

Related Blog