Do you understand what the surface drawing treatment of aluminum sheet plates? As one of the most important step of the aluminum sheet plate for sale, the so-called wire drawing is actually a repair process. For example, if there are scratches on the metal surface, it can be drawn by a wire drawing machine to make consistent scratches on the surface, so that the original scratches can be submerged. Therefore, Drawing can not only remove scratches on the surface of metal sheets, but also beautify the appearance of metal sheets. It can be said to kill two birds with one stone.

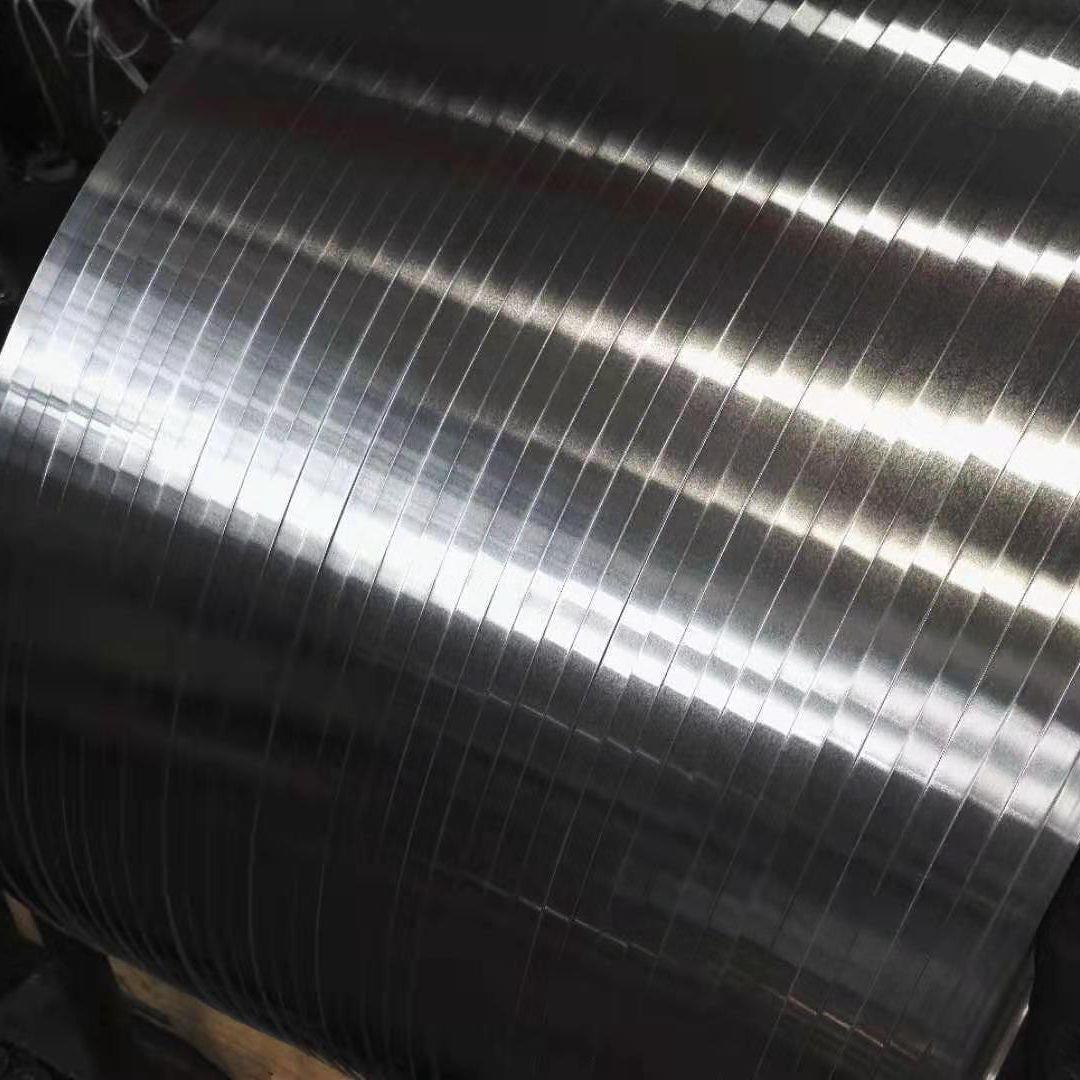

1. Straight grain drawing refers to processing straight lines on the surface of the aluminum plate by mechanical friction. It has the dual function of brushing off scratches on the surface of the aluminum plate and decorating the surface of the aluminum sheet plate. There are two kinds of straight wire drawing: continuous wire grain and intermittent wire grain. The continuous silk pattern can be obtained by rubbing the surface of the aluminum plate for sale continuously horizontally and straightly with a scouring pad or a stainless steel brush. By changing the diameter of the steel wire of the stainless steel brush, different thicknesses of lines can be obtained.

2. Intermittent silk patterns are generally processed on a brushing machine or a wiping machine. The production principle is to use two sets of differential wheels rotating in the same direction. The upper set is a fast-rotating grinding roller, and the lower set is a slow-rotating rubber roller. The aluminum or aluminum sheet plate passes through the two sets of rollers and is brushed out. Delicate interrupted straight lines.

3. Chaotic wire drawing is a kind of irregular and non-obvious matte silk pattern obtained by moving the aluminum plate back and forth, left and right, and rubbing under the high-speed copper wire brush. This kind of processing has higher requirements on the surface of the aluminum or aluminum sheet plates.

4. The ripples are generally made on a brushing machine or a wiping machine. Using the axial movement of the upper set of grinding rollers, the surface of the aluminum or aluminum sheet plates is brushed to obtain a wave pattern.

5. Spin pattern, also known as optical rotation, is a kind of silk pattern obtained by rotating and polishing the surface of aluminum or aluminum sheet plate by using cylindrical felt or nylon wheel for grinding stone on the drilling machine, mixing polishing ointment with kerosene. It is mostly used for decorative finishing of circular signs and small decorative dials.

6. The thread is to use a small motor with a circular felt on the shaft, fix it on the table, and make an angle of about 60 degrees with the edge of the table, and make a pallet with a fixed aluminum plate to press the tea. A strip of mylar with straight edges is attached to the board to limit thread competition. Using the rotation of the felt and the linear movement of the carriage, a thread pattern with the same width is rubbed on the surface of the aluminum sheet plates.

* Thank you for your inquiry. Please provide your business needs information so that we can better serve you.

This information can help us assign the most suitable person to solve your problem. We will give you feedback within 1-2 working days.

Related Blog