What are the factors related to the heat sealing strength of vacuum aluminum foil bags?

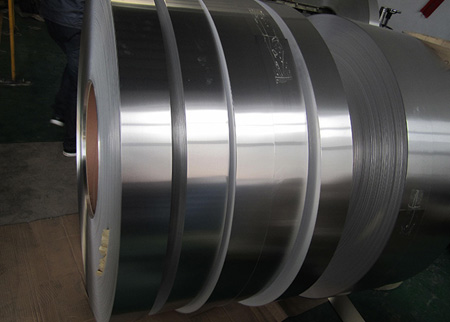

1. In terms of raw and auxiliary materials: the original aluminium foil is the carrier of the adhesive layer, and its quality has an important influence on the heat sealing strength of vacuum aluminium foil bags. On the one hand, the surface oil of the original aluminium foil will weaken the adhesion between the adhesive and the original aluminium foil. On the other hand, the heat sealing strength is also related to the metal composition of the original aluminium foil and the surface luminosity is not enough to affect the heat sealing strength, so the quality of the original aluminium foil should be strictly controlled.

2. Adhesives: Adhesives are special substances containing solvents, which are coated on the dark side of the original aluminium foil under the appropriate process conditions and dried in the drying channel to form a bonding layer, which plays a decisive role in the heat sealing strength of the product.

3. Production process: Under the control of the corresponding process parameters, the adhesive is coated on the surface of the original aluminium foil to form a film, the quality of the film will directly affect the heat sealing strength of the product. One of the more important parameters such as coating speed. If the coating speed is too fast, the temperature of the drying channel is too high, the solvent on the surface of the coated film will evaporate too quickly, resulting in the residual solvent in the film, the coating film is not sufficiently dry, which will affect the heat sealing strength of the vacuum aluminum foil bag.

4. Heat sealing temperature: Heat sealing temperature is an important factor affecting the strength of heat sealing. If the temperature is too low, the bond between the adhesive layer and pvc film will not be solid. If the temperature is too high, and will make the inside of the goods affected. Therefore, the reasonable heat sealing temperature is generally between 150°C and 160°C.

5. Heat sealing pressure: to achieve the ideal heat sealing strength, you need to set the corresponding heat sealing pressure. If the pressure is not enough, the adhesive layer of the vacuum aluminum foil bag and pvc film can not be fully laminated heat sealing, so it can not achieve good heat sealing effect.

6. Heat sealing time: heat sealing time will also affect the heat sealing strength. In general, under the same heat sealing temperature and pressure, a longer heat sealing time can make the heat sealing parts seal more firmly and perfectly, and can better achieve the expected heat sealing strength. If the heat sealing time is too short, the heat sealing between the adhesive layer and the pvc film will not be sufficient.

* Thank you for your inquiry. Please provide your business needs information so that we can better serve you.

This information can help us assign the most suitable person to solve your problem. We will give you feedback within 1-2 working days.

Related Blog