The production process of aluminium foil lunch boxes

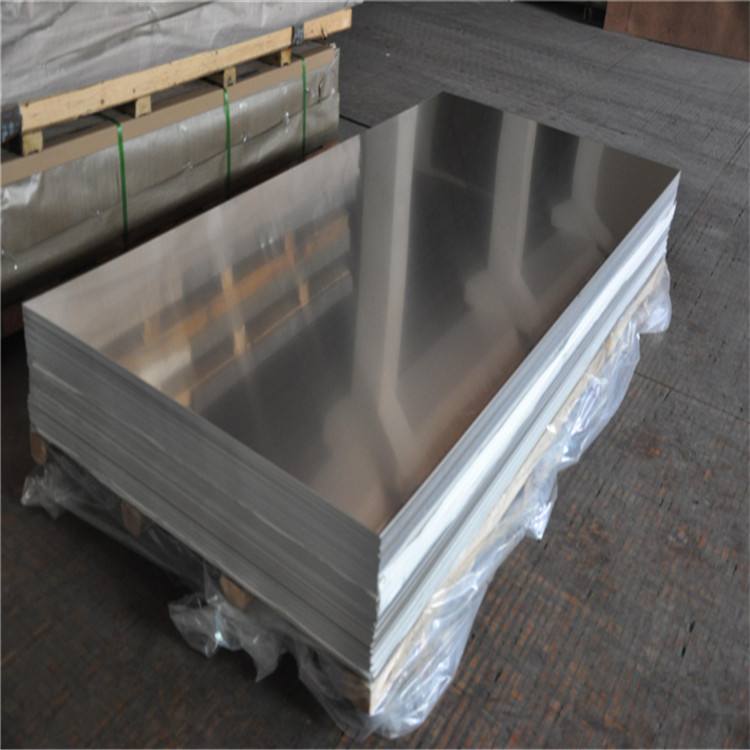

Aluminium foil lunch boxes are a widely used type of tableware. The thickness of an aluminium foil box is generally between 0.05mm and 0.29mm and can be divided into two types: wrinkled and wrinkle-free. They can also be divided into disposable and reusable. They are often called tinfoil lunch boxes in China. A roll of aluminium foil with a smooth surface, no pinholes, no dust particles and no odour. The production process is fully automatic cold stamping and forming by special equipment and moulds.

The production process of aluminium foil lunch boxes is divided into six steps: spreading → oiling → feeding → dropping → stamping → testing. During the production process, the aluminium foil is subjected to punching pressures of up to 40-80 tons and a stamping frequency of 1 to 2 seconds.

The process of making an aluminium foil lunch box is to put the raw material of aluminium foil on the production line down the track to the stamping machine, a vigorous out of miracle stamping... The pattern is made directly on the mould and with an up and down squeeze, the aluminium foil is made to look like a fast food box. The stamped boxes are then taken by airflow to the assembly line before being collected and sterilised and boxed by workers.

* Thank you for your inquiry. Please provide your business needs information so that we can better serve you.

This information can help us assign the most suitable person to solve your problem. We will give you feedback within 1-2 working days.

Related Blog