Talking about the technology of aluminum surface treatment, many customers might be a bit stunned. Well, what is it? What does it mean? When do I need to know it? Click the title and find out more!

The influence of the purity of the aluminum surface treatment on the quality of the aluminum oxide film on the quality of the aluminum oxide film before oxidation has long been known by scientific and technological workers. However, in industrial production, the surface processing quality of domestic aluminum products seriously affects the quality of anodized products, and this contradiction is becoming more and more prominent. The foreign aluminum products are all milled, smooth as a mirror, and of excellent quality after oxidation.

Some shoddy aluminum materials often have low gloss, bubbles, scratches, and heavy skin roughness. After anodizing, these defects are still exposed. Processes with strong decorative properties, such as various pattern printing, thermal transfer printing, etc., are particularly serious due to the poor quality and surface state of the sheet. Therefore, improving the appearance quality of the sheet has become an important part of ensuring the best quality of the oxidation of aluminum products. Oxidation process Sulfuric acid method, oxalic acid method, chromic acid method, especially sulfuric acid anodizing method, are almost unknown to everyone who is engaged in aluminum surface treatment of aluminum products. Each of these oxidation methods has its own characteristics and scope of application. For example, the oxalic acid method can obtain a thicker oxide film layer, and the oxide film itself has some decorative colors, but this method has high cost and large power consumption. The oxide film layer of the sulfuric acid method is transparent and colorless, and has good color absorption performance. In addition, the composition of the electrolyte is simple and stable, the process operation is easy, and the cost is low, so it is more widely used. Install refrigeration equipment, which again becomes a difficulty. In Japan, the sulfuric acid-oxalic acid mixed acid oxidation method has long been developed, taking the advantages of the two and avoiding the disadvantages of the two, and has become the main oxidation bath in Japan.

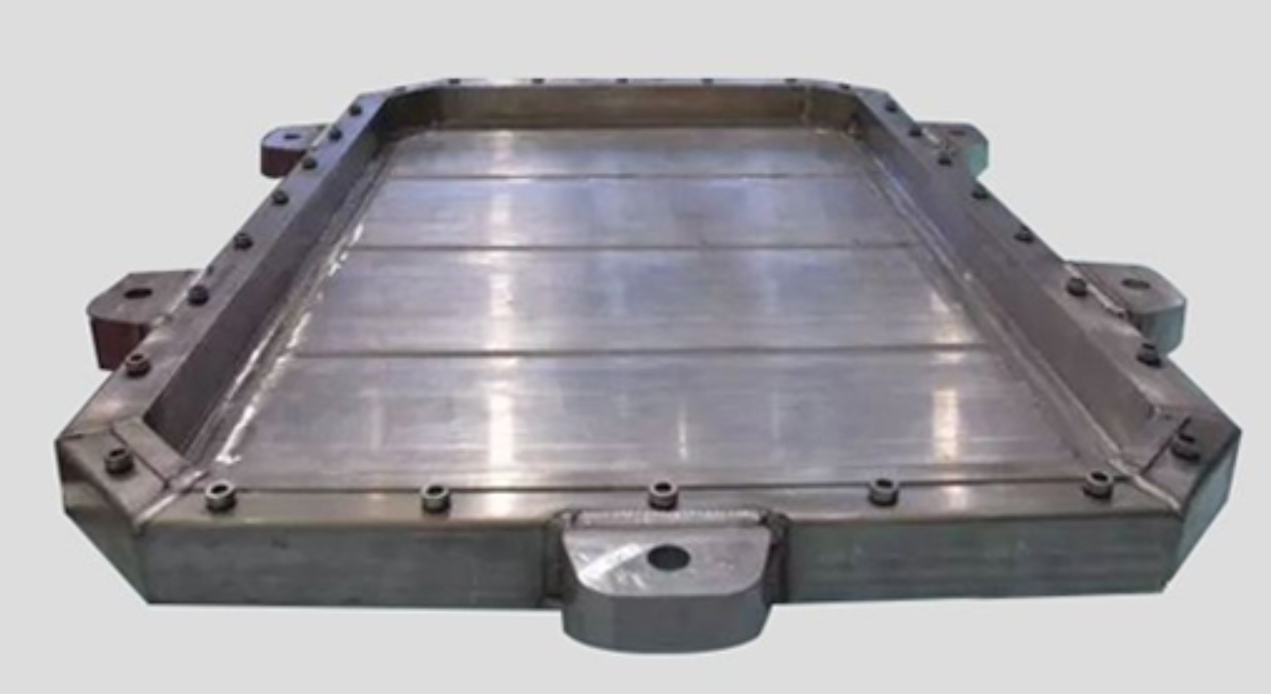

We Haomei also often learn other advanced technology. Now we are proficient in using various surface treatment methods of aluminum products, and also have many hot rolling mills and molds. If you have any material surface requirements or requirements, please contact us! We welcome personal customization!

* Thank you for your inquiry. Please provide your business needs information so that we can better serve you.

This information can help us assign the most suitable person to solve your problem. We will give you feedback within 1-2 working days.

Related Blog