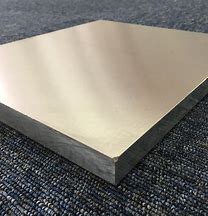

Mold aluminum plates are essential components in the manufacturing of molds in various industries. They come in different sizes, thicknesses, and grades, making them highly versatile and suitable for different applications. The specifications of the mold aluminum plate play a significant role in determining the quality of the final product and the efficiency of the manufacturing process.

One of the most critical features of mold aluminum plates is the material used. Aluminum alloy is the most common material used to make mold aluminum plates. It is known for its high strength, corrosion resistance, and excellent machinability, making it an ideal choice for mold making. Different grades of aluminum alloy are used in the production of mold aluminum plates, such as 6061, 7075, 5083, and 2024. These grades have varying properties that make them suitable for specific applications. For instance, 7075 aluminum alloy is known for its high strength and durability, while 6061 aluminum alloy is known for its excellent machinability and weldability.

The thickness of the mold aluminum plate is another critical specification that should be considered when selecting a mold aluminum plate. The thickness of the plate varies depending on the specific application, ranging from 1mm to 500mm. The thickness of the plate determines the durability of the mold and the accuracy and precision of the final product. For example, thicker plates are required for larger molds that will be used to produce larger products.

The width and length of the mold aluminum plate are also crucial specifications to consider. The width ranges from 100mm to 2000mm, while the length ranges from 100mm to 6000mm, depending on the application. Manufacturers must consider the size of the product they want to produce and the number of molds needed to meet production requirements. The width and length of the mold aluminum plates determine the size of the final product and the number of molds that can be produced at a time.

Choosing the right mold aluminum plate that meets the specific requirements of the application is critical. Working with a reputable supplier can help ensure that the mold aluminum plate meets the required specifications, resulting in high-quality molds and products. The use of high-quality mold aluminum plates can improve the efficiency of the manufacturing process, reduce production costs, and improve the quality of the final product.

In summary, the specifications of mold aluminum plates are essential in the manufacturing of molds. The material used, the thickness, width, and length are critical specifications that should be considered when selecting a mold aluminum plate. Manufacturers must consider the specific requirements of the application to determine the appropriate grade, thickness, width, and length.

* Thank you for your inquiry. Please provide your business needs information so that we can better serve you.

This information can help us assign the most suitable person to solve your problem. We will give you feedback within 1-2 working days.

Related Blog