Pharmaceutical aluminum foils are an essential component of medicine packaging due to their excellent barrier properties against light, moisture, and gases. They are widely used to package various forms of medicines, including tablets, capsules, powders, and liquids, to ensure their safety, efficacy, and shelf-life. In this essay, we will discuss the different types, materials, prices, prospects, and other information related to pharmaceutical aluminum foils.

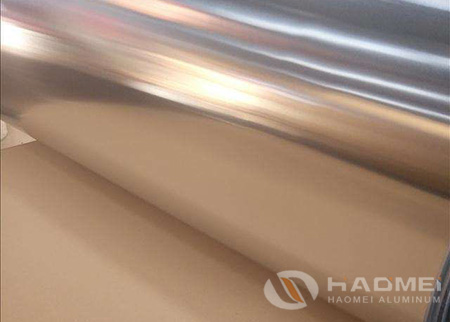

There are two main types of pharmaceutical aluminum foils: blister packs and strip packs. Blister packs are the most common type and consist of a cavity or pocket made of a formable web, usually a thermoformed plastic, such as PVC, PVDC, or PVC/PVDC, and a lid made of aluminum foil. The lid can be either push-through or peelable, depending on the needs of the customer. Push-through lids are used for tablets and capsules, while peelable lids are used for powders and liquids. Strip packs, on the other hand, consist of a strip of aluminum foil with one side coated with heat-sealable lacquer and the other side with print primer for printing ink adhesion. Strip packs are used for medicines that need to be dispensed one by one, such as birth control pills and cough drops.

The most commonly used material in pharmaceutical aluminum foils is aluminum alloy 8011, which has good ductility, formability, and weldability. It is also food-grade and compliant with the US FDA and European Union regulations. Other materials that can be used include aluminum alloys 8021 and 8079, which have higher strength and better barrier properties against oxygen and moisture, and can be used for high-barrier blister packs. The choice of material depends on the specific needs of the customer, such as the type of medicine, the desired shelf-life, and the regulatory requirements.

The price of pharmaceutical aluminum foils depends on several factors, such as the type, material, thickness, width, and length. Blister packs are generally more expensive than strip packs due to their higher complexity and material usage. Aluminum alloy 8011 is the most affordable option, while alloys 8021 and 8079 can be up to 50% more expensive. The thickness of the foil also affects the price, with thicker foils being more expensive. The width and length of the foil are usually customized to the specific needs of the customer and can affect the price accordingly. However, the cost of pharmaceutical aluminum foils is relatively low compared to the overall cost of medicine production and distribution.

* Thank you for your inquiry. Please provide your business needs information so that we can better serve you.

This information can help us assign the most suitable person to solve your problem. We will give you feedback within 1-2 working days.

Related Blog