Today we going to talk about new energy vehicle aluminum alloy for sale. Nowadays, the automotive industry is developing rapidly, but the energy problem is becoming more and more urgent, and the environmental problems brought by automobiles are also attracting much attention. The development of new energy vehicle industry is an effective way to alleviate the energy crisis, reduce greenhouse gas emissions and reduce environmental pollution, and at present, new energy vehicles have become an important direction for the transformation and development of the automotive industry.

New energy vehicles are different from traditional vehicles, is the use of batteries as a power to drive the operation of the car, which is subject to the weight of the power battery, the cruising range of the power battery and the high pressure of the automobile energy-saving and emission reduction policy, in the vehicle design and material application, its body lightweight has become the first consideration of car companies. Therefore, battery-powered new energy vehicles are more in urgent need of body weight reduction than traditional vehicles. This also opens up a broader market space for lightweight materials such as aluminum.

In the automotive lightweight materials, the comprehensive cost performance of aluminum alloy materials is higher than that of steel, magnesium, plastics and composite materials, and it has great advantages in terms of application technology, operational safety and recycling. The density of aluminum is only 1/3 of steel, and its weight reduction and energy-saving effects are obvious, and it can better improve riding comfort under the premise of ensuring safety. At the same time, aluminum is easier to recycle. The comprehensive cost-performance advantages of aluminum determine that it is the best choice for automotive lightweight applications.

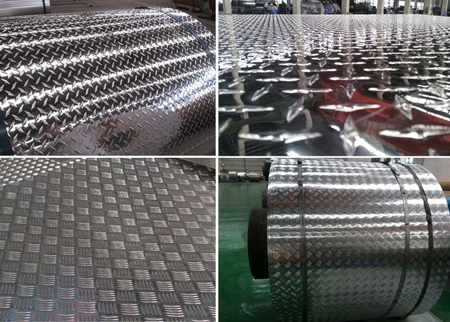

The application parts of aluminum in new energy vehicle parts mainly include body, wheels, chassis, anti-collision beams, power batteries, etc. According to the classification of processing forms, automotive aluminum is mainly divided into three forms: die-casting, extrusion and calendering, of which the amount of die-casting parts accounts for about 80%, and the extrusion and calendered parts each station are about 10%. Die-cast parts are mainly used in engines, wheels and other parts, extrusion parts are mainly used for cars, luggage racks, door beams, etc., and calendered parts are mainly used to produce aluminum plates for car bodies.

* Thank you for your inquiry. Please provide your business needs information so that we can better serve you.

This information can help us assign the most suitable person to solve your problem. We will give you feedback within 1-2 working days.

Related Blog