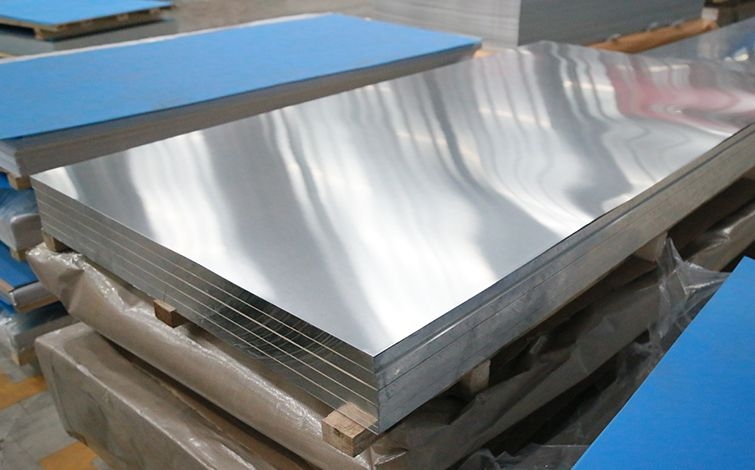

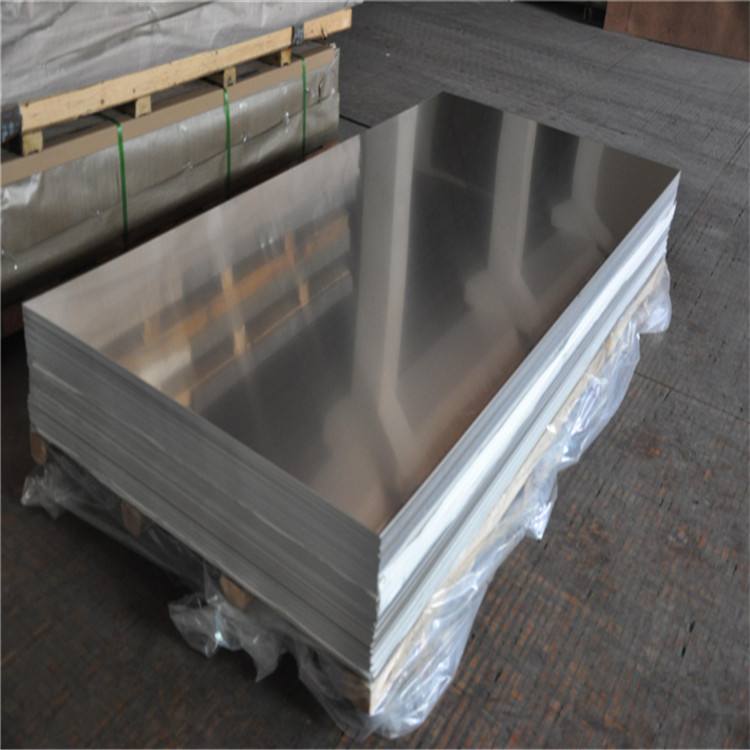

Introduction of 1050A aluminum plate

Rectangular sheet processed by rolling aluminum ingots

1050A is formed by adding a small amount of iron to pure aluminum, which has excellent forming characteristics, high corrosion resistance, good weldability and electrical conductivity. 1050A is widely used in products that do not require high strength, such as chemical instruments, sheet processing parts, deep drawing or spinning concave ware, welded parts, heat exchangers, clock surfaces and plates, nameplates, kitchenware, decorations, reflective appliances, etc.

1050A and 1060 are industrial pure aluminum, the aluminum content (mass fraction) is 99.50% and 99.60%, respectively, and cannot be heat treated to strengthen. Pure aluminum has a silvery-white surface and its density decreases with increasing purity or temperature. They have high electrical and thermal conductivity, good plasticity, easy to withstand various pressure processing and bending, extension, but low strength. The candlelight performance and welding performance of industrial pure aluminum are better, and gas welding, hydrogen atom welding and resistance welding can be carried out, but its machinability is poor.

One of the outstanding characteristics of industrial pure aluminum is good corrosion resistance, which is due to the strong tendency of aluminum to combine with oxygen, forming a layer of oxide film on the surface of aluminum in the air, preventing the continued oxidation of aluminum, so that aluminum has good corrosion resistance. 1050A and 1060 are widely used in electrical conductors, chemical storage tanks, hoses for the brewing industry, food containers, cookware, heat exchangers, decorative materials, etc.; It is also used to make welding rods and aluminum powder, and its welding rods are used to weld aluminum plates and pure aluminum containers, and its aluminum powder is used as fireworks powder.

* Thank you for your inquiry. Please provide your business needs information so that we can better serve you.

This information can help us assign the most suitable person to solve your problem. We will give you feedback within 1-2 working days.

Related Blog