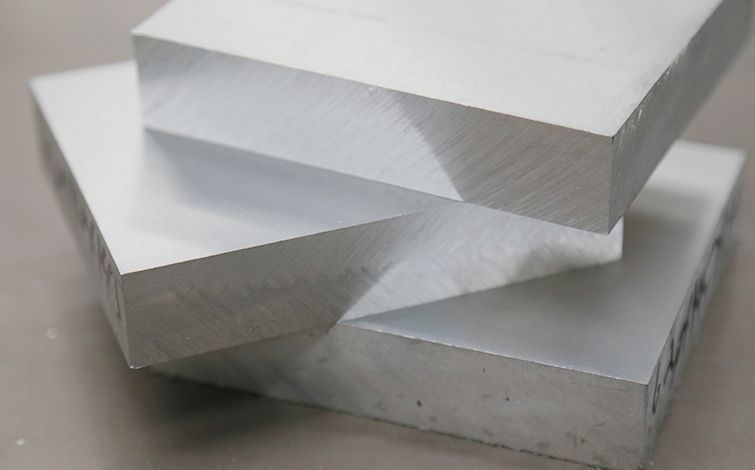

1100 aluminum coils is a very common aluminum material for sale in life. Everyone knows that aluminum is easy to corrode, so what is the cause of oxidative corrosion of aluminum coils? Reasons for corrosion of 1100 aluminum coils: Corrosive oxidation refers to aluminum Before the roll is not used, the surface of the aluminum roll is not completely in contact with the air because of the packaging state, and the protective layer has not yet formed. In this case, if the aluminum coil enters the water, after being rained or damp, the water in the moisture will chemically react with the surface of the aluminum coil, causing corrosion of the aluminum coil. The corroded aluminum coil will show signs of corrosion, and in severe cases, it will turn black and black, as if it had been burned by fire. So how should we prevent corrosion of 1100 aluminum coils? Let's look at a few suggestions!

1. Where there is rain or snow on the roof of workshops and warehouses, aluminum coils should not be placed.

2. Strengthen the management of air drying to ensure that there is no water in the compressed air.

3. The packaging of aluminum foil rolls should be sealed, and an appropriate amount of desiccant should be placed in each roll.

4. When the 1100 aluminum coil is transported from a low temperature area to an area with high temperature and high humidity, do not open the sealed package immediately.

5. Strengthen the management of rolling oil and control its water content below 0.04%.

6. The humidity of the wooden shaft and box board of the packing box should not be greater than 18%, and the temperature of packing colored 1100 aluminum coils should not be greater than 45°C.

Oxidation under normal conditions means that after the aluminum coil is used, for example, after being wrapped on a pipe, the surface of the aluminum coil will be completely in contact with the air to form an oxide film. This layer of oxide film will protect the aluminum coil for sale from further corrosion, so after use, even if it is exposed to rain or outdoors, the 1100 aluminum coils will not corrode. So we have to deal with this oxidation depending on the situation! This is the introduction of the reasons for oxidative corrosion of 1100 aluminum coils and how to deal with them! Hope our customers can pay attention to these in the process of use, so that the product does not rust and does not meet your needs!

* Thank you for your inquiry. Please provide your business needs information so that we can better serve you.

This information can help us assign the most suitable person to solve your problem. We will give you feedback within 1-2 working days.

Related Blog