Electronic foil and battery foil

Electronic aluminium foil: this means light foil, the key raw material for the production of aluminium electrolytic capacitors, which is divided into electronic aluminium foil and electrode foil due to the sequence before and after the production process, where electrode foil includes corroded foil and chemical foil. Capacitor foil is a corrosive material that works under polar conditions and has high requirements for the organisation of the foil. There are three types of aluminium foil used: cathode foil 0.015-0.06mm thick, high voltage anode foil 0.065-0.1mm thick and low voltage anode foil 0.06-0.1mm thick. The anode foil is made of industrial high purity aluminium, the mass fraction of which should be greater than or equal to 99.93%, while the purity of aluminium for high voltage anodes should be greater than or equal to 4 N. The Chinese standard only specifies the content of Fe, Si and Cu, while the content of other elements Mg, Zn, Mn, Ni and Ti is not clearly specified, and the impurity content of aluminium foil for foreign batteries is significantly lower than that in China.

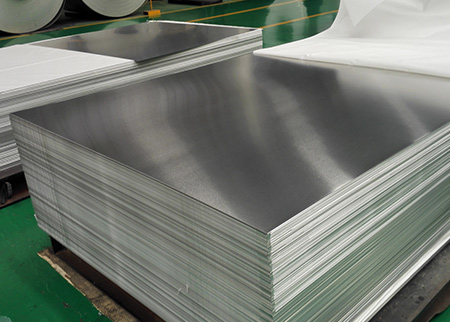

Battery aluminium foil: used as a collector for lithium ion batteries. Typically, the lithium-ion battery industry uses rolled aluminium foil as the positive collector. The thickness of the rolled foil varies from 10 to 50 microns. Commonly used pure aluminium foils for lithium batteries are available in various alloy grades such as 1060, 1050, 1145, 1235, etc. and in states such as -O, H14, -H24, -H22 and -H18.

* Thank you for your inquiry. Please provide your business needs information so that we can better serve you.

This information can help us assign the most suitable person to solve your problem. We will give you feedback within 1-2 working days.

Related Blog