Classification and type analysis of aluminum oxidation processing

There are two main types of aluminum oxidation processing:

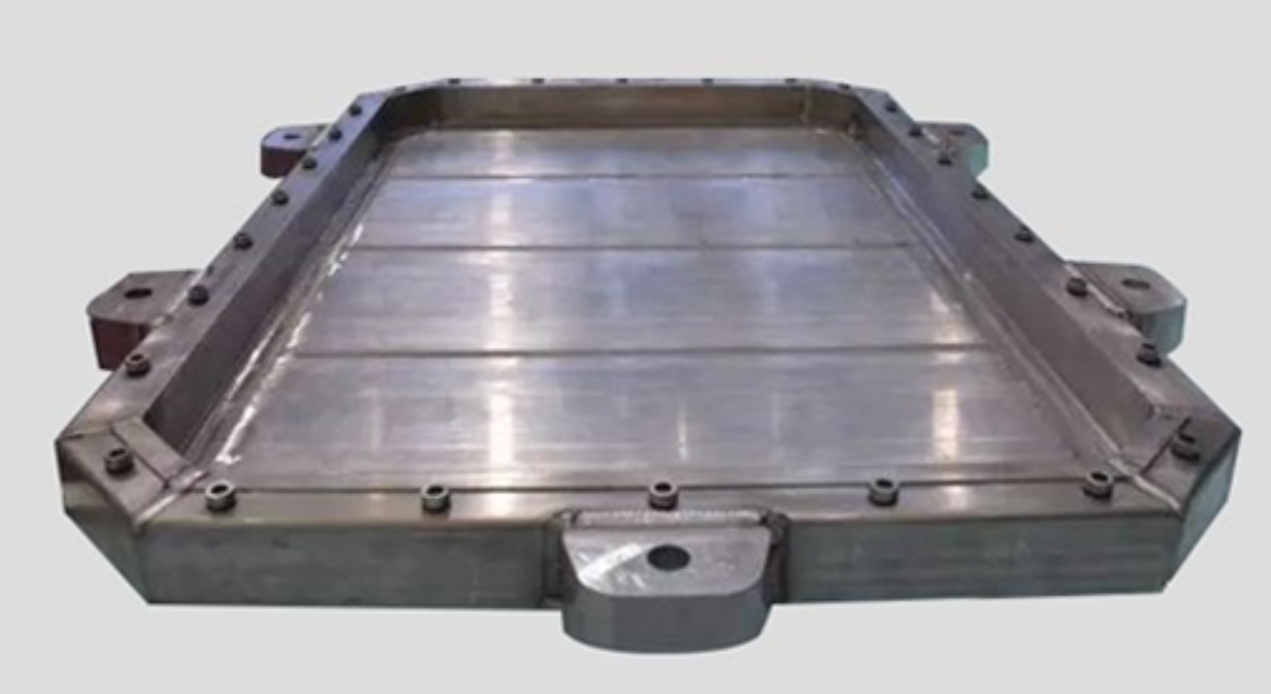

(1) Chemical oxidation, the oxide film is thin, the thickness is about 0.5~4 microns, and porous, soft, with good adsorption, can be used as the bottom layer of organic coating, but its wear resistance and corrosion resistance are not as good as anodized film;

(2) Electrochemical oxidation, the thickness of the oxide film is about 5~20 microns (the thickness of the hard anodized film can reach 60~200 microns), with high hardness, good heat resistance and insulation, corrosion resistance is higher than that of chemical oxide film, porous, and has good adsorption capacity. The chemical oxidation treatment equipment of aluminum and aluminum alloy is simple, easy to operate, high production efficiency, does not consume electric energy, has a wide range of applications, and is not limited by the size and shape of parts.

The chemical oxidation process of aluminum and aluminum alloy can be divided into two categories according to its solution properties: alkaline oxidation method and acid oxidation method.

According to the nature of the film layer, it can be divided into: oxide film, phosphate film, chromate film, chromatic acid-phosphate film. Aluminum is a relatively active metal, the standard potential is -1.66V, in the air can naturally form a layer of oxide film thickness of about 0.01 ~ 0.1 microns, this layer of oxide film is amorphous, thin and porous, poor corrosion resistance. However, if aluminum and its alloy are placed in an appropriate electrolyte, aluminum products are used as the anode, and an oxide film is formed on the surface under the action of an applied current, this method is called anodic oxidation.

By selecting different types and concentrations of electrolytes, as well as controlling the process conditions during oxidation, anodized films with different properties and thicknesses of about tens to hundreds of microns can be obtained, and their corrosion resistance, wear resistance and decoration have been significantly improved and improved. There are many methods of anodizing aluminum and its aluminum alloy, commonly used are sulfuric acid anodizing, chromic acid anodizing, oxalic acid anodizing, hard anodizing and porcelain anodizing.

* Thank you for your inquiry. Please provide your business needs information so that we can better serve you.

This information can help us assign the most suitable person to solve your problem. We will give you feedback within 1-2 working days.

Related Blog