Usually, the curtain wall aluminum plate for sale uses composite aluminum plate as raw materials. The composite aluminum plates are made of two layers of 0.5mm pure aluminum plates (0.2-0.25mm for indoor use) and polyethylene (PE or polyvinyl chloride PVC) with a thickness of 3-4mm in the middle layer. For an instance, you can use flat plates with sizes such as 1220mm×2440mm. The fluorocarbon paint on the surface of the external composite aluminum plate is also completed by roller coating, rolling and heat sealing at one time, and the thickness of the coating is generally about 20 μm. The advantages of using the composite aluminum plates instead of other materials are that, it has light weight, smooth surface, good flatness, no chromatic aberration in the same direction, and excellent on-site machinability. Composite aluminum plate can be used to deal with the dimensional changes of the exterior wall caused by on-site construction errors, reduce the workshop processing cycle and shorten the installation period when used for the curtain wall.

The panels of composite aluminum panels are processed into curtain wall aluminum plate during installation. First of all, the board should be cut according to the size of the secondary design. When cutting the aluminum plates, the size of the folded edge should be considered. Generally, about 30mm is added on each side. According to the introduction of the curtain wall installation company's requirements, the finished product rate of the cut board is generally 60% to 70%. The cut composite aluminum plate needs four-side planing, that is, cutting off the inner aluminum plate and plastic layer of a certain width, leaving only the outer aluminum plate with a thickness of 0.5mm, and then folding the edges into a 90-degree outside angle, and then using aluminum profiles to make the curtain wall aluminum plate of same size. The auxiliary frame is placed in the bent groove of the composite aluminum-plastic plate. The bottom surface of the auxiliary frame is bonded to the back of the aluminum-plastic plate with structural adhesive, and the folded four sides are fixed on the outside of the auxiliary frame by riveting, and the middle of the auxiliary frame is generally required. There are reinforcing ribs to ensure the mechanical strength of the curtain wall aluminum plate. The reinforcing ribs are made of aluminum and are bonded with structural adhesive. Some informal methods are only fixed by adding aluminum corners to the four corners of the composite panel. The reinforcing ribs are bonded with double-sided tape. Its firmness

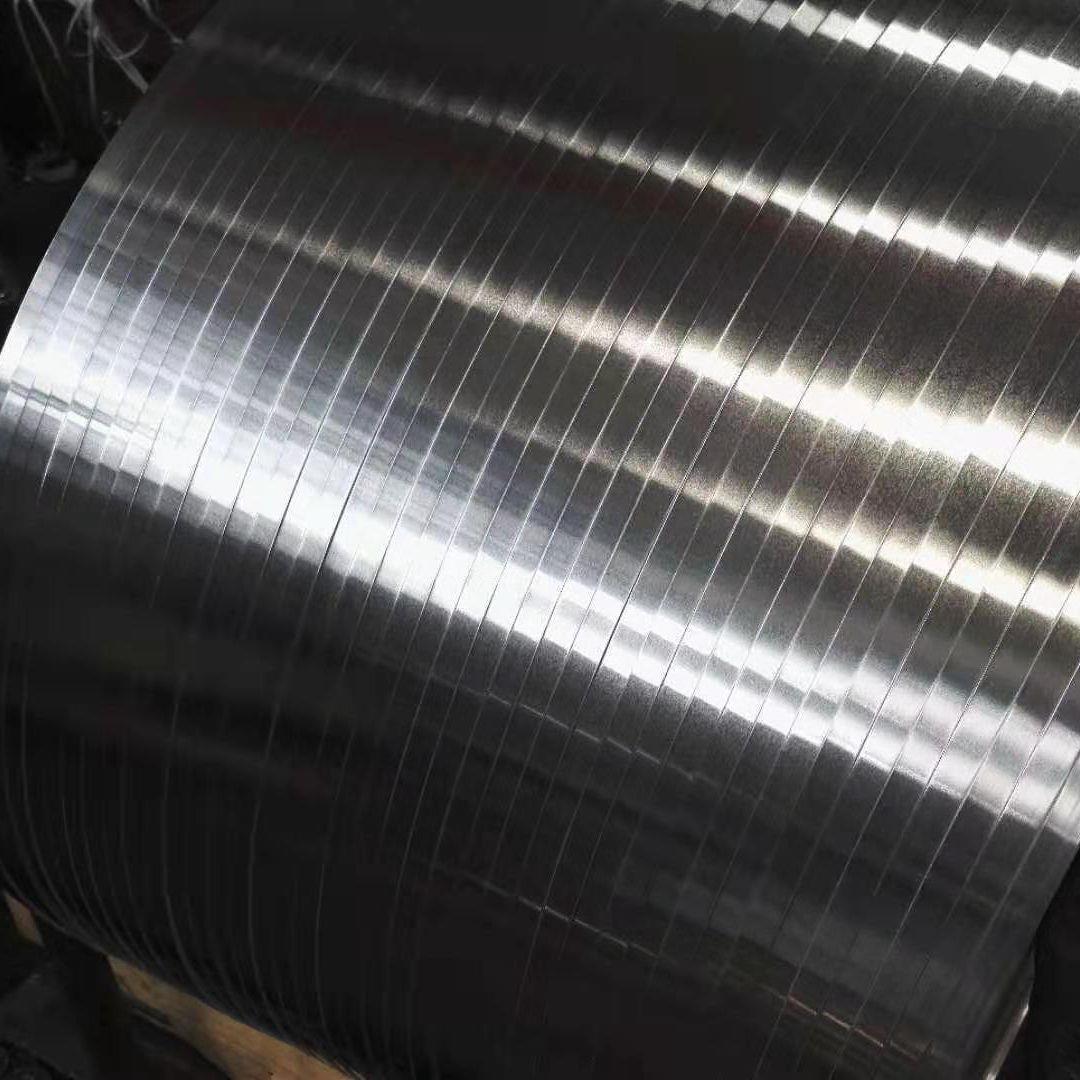

We are manufacturer and supplier of composite aluminum plate and we have it for sale at factory price. There is a large bulk in stock and we welcome to hear from you.

* Thank you for your inquiry. Please provide your business needs information so that we can better serve you.

This information can help us assign the most suitable person to solve your problem. We will give you feedback within 1-2 working days.

Related Blog