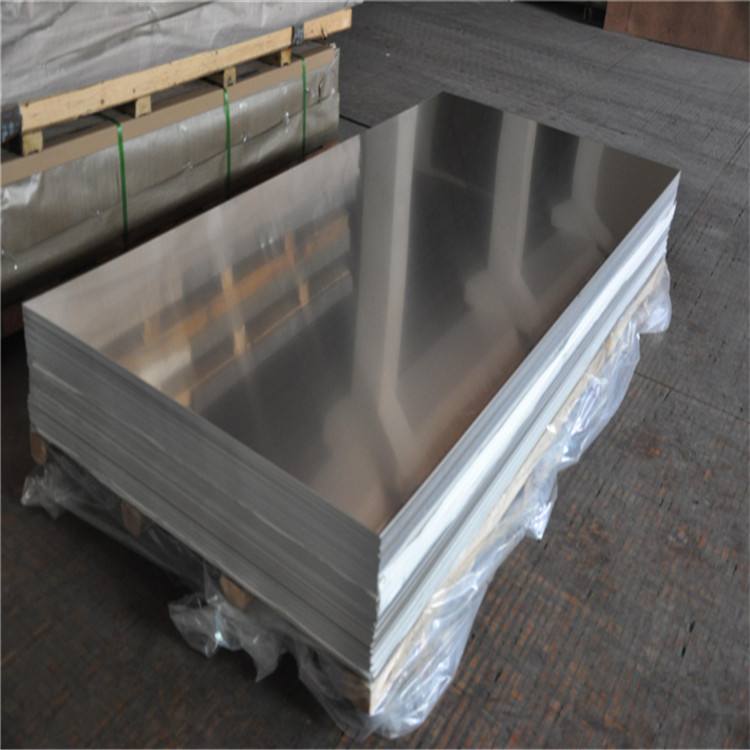

Automotive aluminum alloy is a popular material used in the automotive industry for making vehicle body parts. It has several benefits over other metals, such as:

Automotive aluminum alloy is a lightweight material, which makes it an excellent choice for making vehicle body parts. It is almost three times lighter than steel, which helps to reduce the overall weight of the vehicle, leading to better fuel efficiency and improved performance.

Aluminum alloy has excellent corrosion resistance properties, which is critical for vehicle body parts, as they are exposed to harsh weather conditions. It can resist rust and corrosion, making it a durable and long-lasting material.

Automotive aluminum alloy is a strong material, which makes it suitable for making vehicle body parts. It can withstand high impact and provide better protection to passengers during a collision.

Aluminum alloy is easy to shape, which makes it suitable for making complex vehicle body parts. It can be molded into different shapes and sizes, providing designers with greater flexibility in the design process.

Aluminum alloy is a recyclable material, which makes it an environmentally friendly option for making vehicle body parts. It can be recycled multiple times without losing its properties, reducing the carbon footprint of the automotive industry.

In conclusion, automotive aluminum alloy is an excellent material for making vehicle body parts due to its lightweight, corrosion resistance, high strength, easy to shape, and recyclable properties.

* Thank you for your inquiry. Please provide your business needs information so that we can better serve you.

This information can help us assign the most suitable person to solve your problem. We will give you feedback within 1-2 working days.

Related Blog