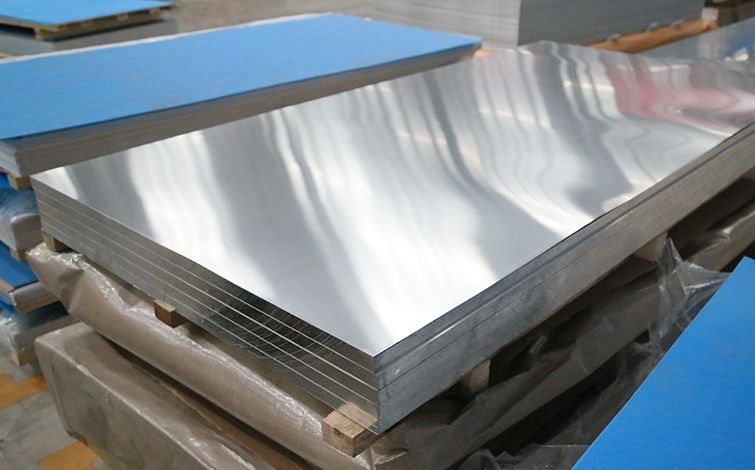

The automotive industry is constantly evolving, and manufacturers are always looking for ways to improve vehicle performance, fuel efficiency, and safety. One of the ways that automotive engineers have been able to achieve these goals is by incorporating lightweight materials into vehicle designs. Aluminum, in particular, has become a popular choice due to its strength, durability, and lightweight properties. In this essay, we will explore the various parts of automotives that can be made of aluminum.

Engine Components

Aluminum is an ideal material for engine components due to its light weight and excellent heat dissipation properties. Engine blocks, cylinder heads, and oil pans are all examples of engine components that can be made of aluminum. The use of aluminum in engine components can reduce the overall weight of the vehicle, which can lead to improved fuel efficiency and performance. Additionally, the use of aluminum in engine components can increase the engine's power output due to its ability to dissipate heat more efficiently than other materials.

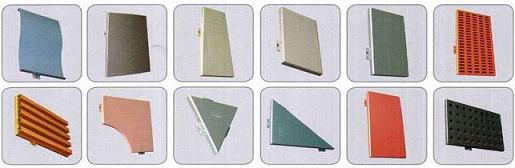

Body Panels

Another area where aluminum is commonly used in automotive design is in the body panels of the vehicle. Hoods, doors, and trunk lids are all examples of body panels that can be made of aluminum. Similar to engine components, using aluminum in body panels can reduce the overall weight of the vehicle, which can lead to improved fuel efficiency and performance. In addition, the use of aluminum in body panels can improve the vehicle's handling and maneuverability due to the reduction in weight.

Wheels

Aluminum wheels are a popular option for many drivers due to their light weight and stylish appearance. In addition to being lighter than traditional steel wheels, aluminum wheels are also more resistant to rust and corrosion. Furthermore, the use of aluminum in wheels can improve the overall performance and handling of the vehicle due to its ability to reduce unsprung weight.

Suspension Components

Aluminum is also commonly used in suspension components such as control arms, knuckles, and sway bars. The use of aluminum in suspension components can reduce the weight of the vehicle, which can lead to improved handling and maneuverability. Additionally, the use of aluminum in suspension components can improve the vehicle's ride quality by reducing unsprung weight.

Conclusion

In conclusion, the use of aluminum in automotive design has become increasingly popular in recent years due to its strength, durability, and light weight. Engine components, body panels, wheels, and suspension components are just a few examples of the many parts of automotives that can be made of aluminum. As automotive engineers continue to search for ways to improve vehicle performance and fuel efficiency, it is likely that we will see even more aluminum components incorporated into vehicle designs in the future.

* Thank you for your inquiry. Please provide your business needs information so that we can better serve you.

This information can help us assign the most suitable person to solve your problem. We will give you feedback within 1-2 working days.

Related Blog