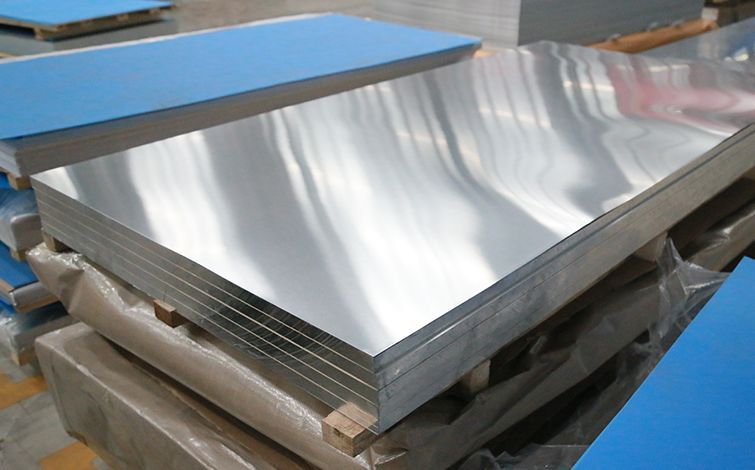

Aluminium alloy sheets are widely used in aircraft, mainly as structural parts for aircraft. Due to its high specific strength and good forming and processing properties, aluminium alloy is the main structural material for aircraft, such as skins, frames, propellers, fuel tanks, wall panels and landing gear struts. The proportion of aluminisation can vary considerably from one aircraft type to another, for example, the Boeing 737 has a large proportion of aluminium alloy material of up to 81%, while the Boeing 787 has 20% aluminium alloy material due to the use of a large number of composite materials.

The aluminium used in aviation is mainly deformed aluminium, with a relatively low proportion of cast material. On average, flat rolled aluminium accounts for 60%, extruded aluminium (tubes, bars, shapes and wires) for 28%, forgings for 7% and castings for 5% of the aluminium consumed in aircraft.

According to the classification of alloy composition, the 2 series and 7 series of aviation aluminium alloys are the main ones. The aluminium alloys used in the structure of large aircraft in the world today are mainly the high strength 2 series (2024, 2224, 2324, 2424, 2524, etc.) and the super high strength 7 series (7075, 7475, 7050, 7150, 7055, 7085, etc.), which account for about 38% and 45% of the aluminium in civil passenger aircraft respectively.

People have carried out in-depth systematic research on aluminium alloys for aerospace in terms of composition and synthesis methods, rolling/extrusion/forging/heat treatment processes, parts processing, material and structural service performance characterization, etc. The development of material products has formed a series, and a series of remarkable results have been achieved in application. In particular, since the late 1980s, with the gradual formation of the damage tolerance and durability design guidelines for aircraft, the strength, fracture toughness, corrosion resistance, fatigue resistance and other comprehensive performance of the material has put forward higher requirements. The current direction of development of aluminium alloy sheets is the development of thick plate materials with low internal stress, and in the manufacturing process a large number of thick plates are used to achieve a whole structural component forming, to replace the previous components assembled with many parts. The widespread use of large monolithic wall plate structures for aviation aluminium alloys has become an important means of improving structural efficiency, reducing the number of parts, lowering costs and shortening development cycles for new generation aircraft. For example, the Boeing B747 aircraft using the whole reinforced wall plate, the number of parts from 129 to 7, the cost reduced by 25%, while the crack extension life and residual strength are increased by three times.

* Thank you for your inquiry. Please provide your business needs information so that we can better serve you.

This information can help us assign the most suitable person to solve your problem. We will give you feedback within 1-2 working days.

Related Blog