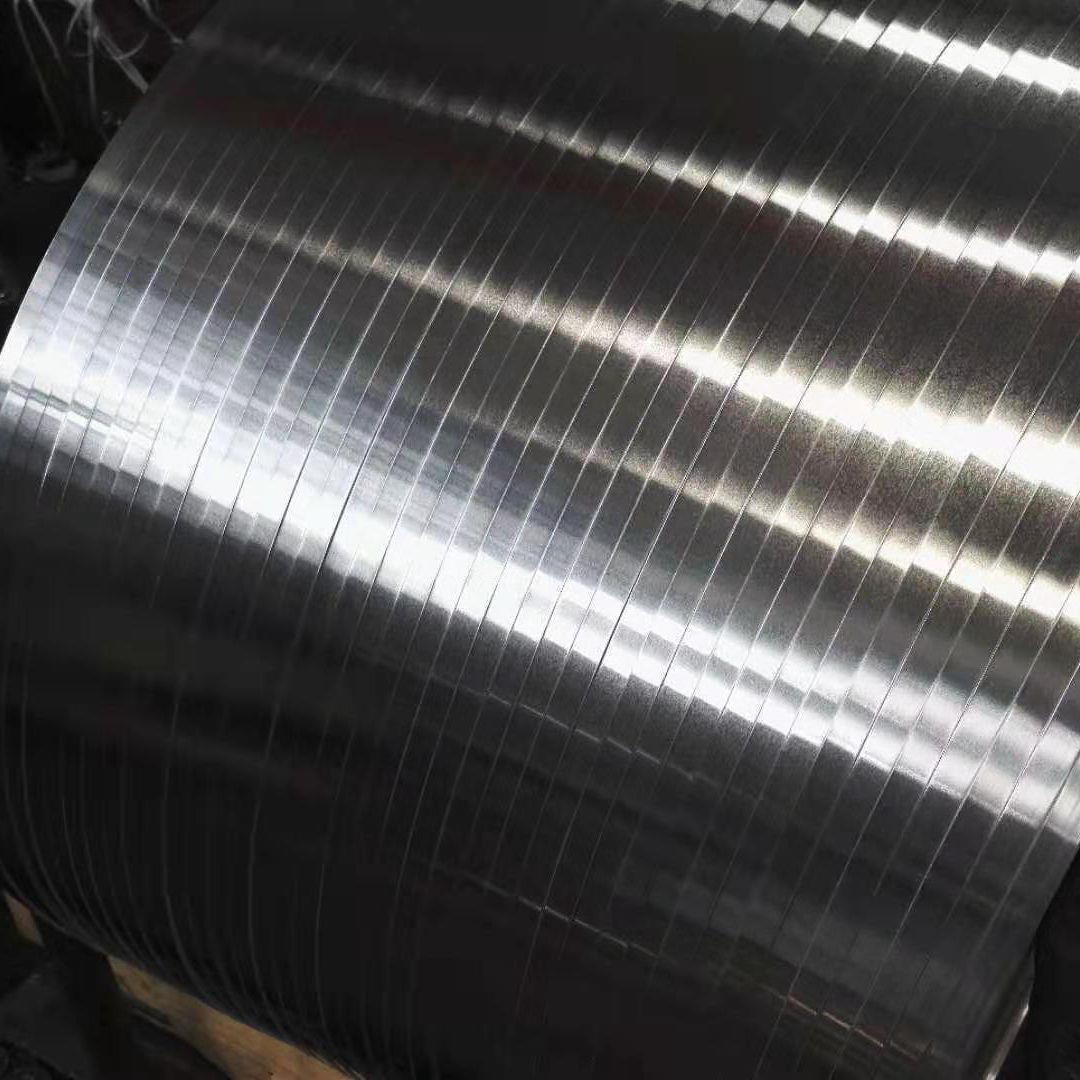

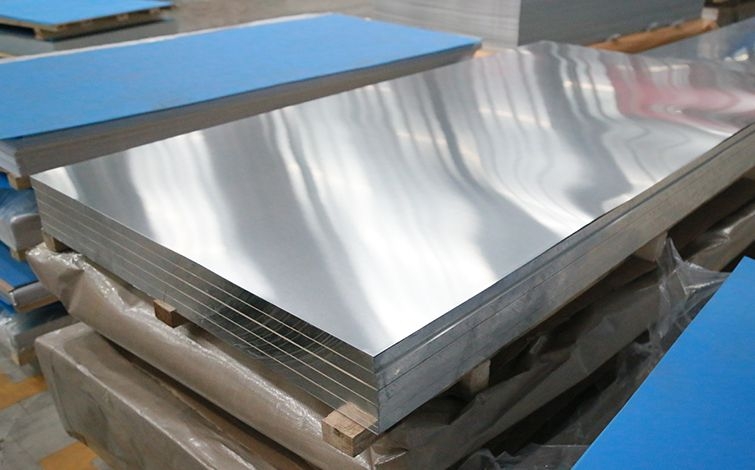

When it comes to transformers, both aluminum and copper foil strips are used in the construction of transformer windings. However, there are several advantages to using aluminum foil strips over copper foil strips.

Cost-effective: Aluminum is significantly cheaper than copper, and this cost difference is even more pronounced when it comes to large transformers. Using aluminum foil strips can result in significant cost savings. This is because copper is a rare and valuable metal, whereas aluminum is the third most abundant element on Earth's crust.

Lightweight: Aluminum is much lighter than copper, which means that transformers made with aluminum foil strips are lighter and easier to transport. This is particularly important for large transformers, where the weight difference can be significant. In addition, the lighter weight of aluminum can also make installation and maintenance easier.

Better thermal conductivity: Aluminum has a higher thermal conductivity than copper, which means that transformers made with aluminum foil strips can dissipate heat more efficiently. This is important because transformers generate heat during operation, and if this heat is not dissipated properly, it can lead to decreased efficiency, premature failure, and even safety hazards.

Easier to work with: Aluminum foil strips are easier to bend and shape than copper foil strips, which makes them easier to work with during the winding process. This is because aluminum is a softer metal than copper, which means that it is more malleable and less likely to crack or break during the winding process. This can help to reduce production costs and increase production efficiency.

Less prone to corrosion: Aluminum is less prone to corrosion than copper, which means that transformers made with aluminum foil strips are more durable and have a longer lifespan. Copper is susceptible to corrosion in the presence of moisture and other environmental factors, which can lead to decreased performance and eventual failure. Aluminum, on the other hand, is much more resistant to corrosion, which means that transformers made with aluminum foil strips can provide reliable performance for longer periods of time.

Overall, while copper foil strips are still commonly used in transformer construction, there are clear advantages to using aluminum foil strips. These advantages include cost-effectiveness, lighter weight, better thermal conductivity, ease of use, and increased durability. As a result, more and more transformer manufacturers are turning to aluminum foil strips as a viable alternative to copper foil strips.

* Thank you for your inquiry. Please provide your business needs information so that we can better serve you.

This information can help us assign the most suitable person to solve your problem. We will give you feedback within 1-2 working days.

Related Blog