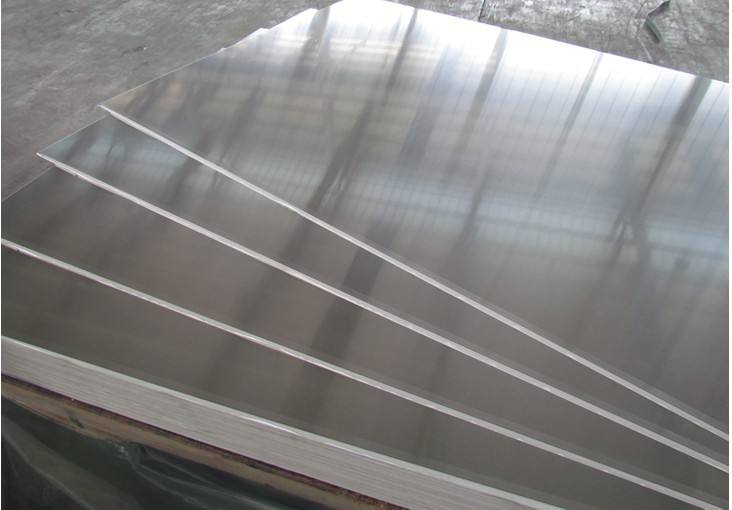

6 series aluminum magnesium silicon alloy characteristics and applications

6 series aluminium alloy plate, the main alloy elements are magnesium and silicon, the representative grades are 6061, with medium strength, good corrosion resistance, weldability, oxidation effect is good. t4, t6 and t651 are the main state. t6 has higher internal stress, processing will be deformed, so t651 is more suitable for processing.

6 series aluminium-magnesium-silicon alloy uses.

6005 extruded profiles and tubes for structural parts requiring a stronger height than 6063 alloy, such as ladders, TV antennas, etc..

6061 requires a certain strength, weldability and high corrosion resistance for various industrial structural properties, such as the manufacture of trucks, tower buildings, ships, trams, furniture, mechanical parts, precision machining with tubes, bars, shapes, plates, etc..

6063 industrial profiles, construction profiles, irrigation pipes and extruded materials for vehicles, pedestals, furniture, fences, etc..

6201 High-strength conductive rods and wires.

6262 threaded, highly stressed parts requiring corrosion resistance superior to that of alloys 2011 and 2017.

6463 architectural and various appliance profiles, and decorative automotive parts with bright surfaces after anodizing.

6A02 aircraft engine parts, forgings and drop-forged parts with complex shapes.

* Thank you for your inquiry. Please provide your business needs information so that we can better serve you.

This information can help us assign the most suitable person to solve your problem. We will give you feedback within 1-2 working days.

Related Blog